Stucco colored front

Color facade plaster refers to the materials used to decorate the exterior walls of buildings. Its main advantage is that this coating allows you to reliably protect the structure from the effects of temperature fluctuations and precipitation and to decorate the surface with a colored decorative layer without the additional use of paint.

The content of the article

Colored plaster for facades

Colored facade plaster is available both in the form of dry compositions requiring dilution with water, and in the form of ready-to-use mixtures. At the latter, the price is higher since the material is used without additional preparation.

Decorative facade color plaster differs in several ways.

- The composition of the material. Astringents - cement, acrylic, silicone resin, water glass, to which various fillers and pigments are added.

- Texture. Using various types of plaster, types of embossed surface of the facade walls are created.

- Fractions of the filler. There are compositions with fine-grained or coarse-grained filler. There are mixtures in which both options are combined.

Varieties of color plaster

A large number of special mixtures are available that ensure high-quality facade decoration. The composition and purpose of the facade color plaster is divided into types. Photos of coating surfaces are presented below.

Mineral plaster

It is made from lime, Portland cement, crumbs from stones of several fractions, clay and modifiers to give greater plasticity and wear resistance. In a limited amount, coloring pigments are added, since a high content of these substances reduces the strength of the material.

Mineral plaster tolerates temperature differences in the range - 30 + 45 ° C. The term of operation is 15 years. The mixture is industrially made as a powder, diluted with water. Used to create simple textures.

For a bright finish, mineral facade plaster is not very suitable - its color scheme is significantly limited. To paint the surface in the desired color is possible only after finishing.

Silicone plaster

For the base, silicone resin is used with the addition of pigments, as well as fillers that increase strength and resistance to ultraviolet rays. It is resistant to salt, making it suitable for decoration in coastal areas.

Suitable for buildings of aerated concrete, concrete blocks and bricks. Also used in the decoration of the basement. Sold as a ready-made solution.

The service life of colored silicone plaster is 20 - 25 years. The decoration is used to create traditional textures.

Acrylic plaster

It is formed from synthetic resins with the addition of modifiers, dyes and fillers (quartz, natural multi-colored marble chips). Minerals produce a shiny surface. It is characterized by durability and strength, resistance to moisture, wind and temperature extremes. The elasticity of acrylic at the base of the mixture reduces the likelihood of cracking.

As the colored acrylic finish becomes dirty, it is recommended to use a water-repellent coating on the surface. Another disadvantage is instability to sunlight - over time, the colors of the coating fade.

Users are offered both in finished form and in the version of the mixture for the addition of tinting paste and giving the necessary color cast. This plaster is not placed on cellular concrete and mineral wool.

The service life is 25 years.

Silicate Plaster

It is made on the basis of liquid potassium glass, after setting the solid material acquiring properties. It has the most elastic structure suitable for decorating building facades. The fraction of the mineral filler may be different, because it depends on what type of surface texture the mixture is intended for.

A wide selection of textures and a wide range of colors for this type of facade plaster are offered. The cost of this material on the market is higher than other types of finishing mixtures, since silicate is resistant to atmospheric precipitation.

It is recommended for laying on walls made of wood, concrete and aerated concrete. It is impossible to cover polymer heaters varnished and painted with oil paint. The mixture is offered as a ready-made solution. Fast setting during finishing eliminates mistakes - it is better to entrust the work to professionals.

Types of textures of facade color plaster

Using mixtures with fillers of certain fractions and special tools (roller, sponge, brush, grater), you can create the desired surface texture.

Among the colored facade plaster there are different types of textures:

- "Fur coat". It is formed by a special technique of laying the mixture on the wall surface.

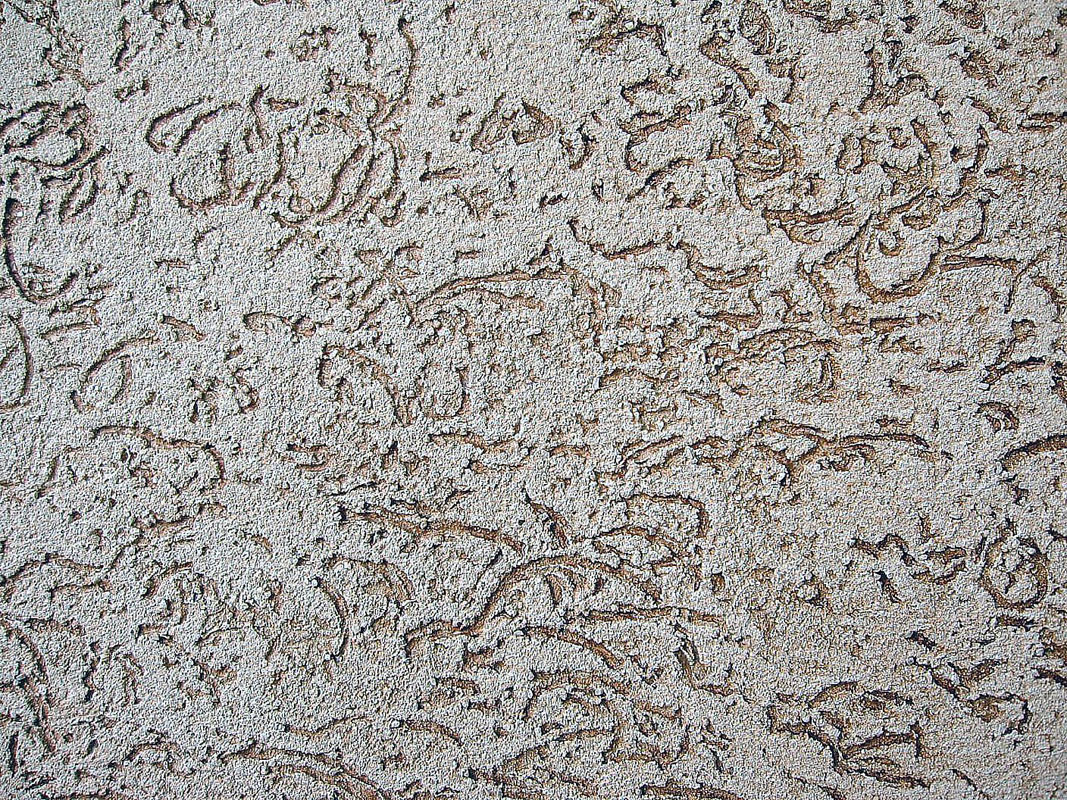

- The bark beetle. Stone grains are added to the mixture, fractions of which affect the saturation of the layer. This creates a surface relief similar in texture to a tree eaten by a bark beetle.

- "Lamb". A stone of various fractions is added to the mixture, due to which a tuberous relief is created.

- "Groats" (pebble). Formed with a mixture of pebbles of a large fraction. The fine-hilly relief resembles croup in appearance.

- Mosaic. It is created using acrylic mixtures with decorative stone.

Stucco manufacturers

Among the manufacturers of colored stucco for facades, the following companies stand out.

- Knauf. It was founded in 1932 in Germany. Offers mineral plaster. Advantages - ease of use, versatility, quick drying, hygroscopicity and ability to retain moisture. The disadvantage is the cost of Knauf plaster, which is higher than that of competitors.

- Baumit. The Austrian concern supplies silicone, silicate and acrylic facade color plaster, characterized by a long service life. Baumit products withstand temperature extremes and do not accumulate moisture, and the market is offered at an affordable price.

- Kaparol. The brand is part of the German Deutsche Amphibolin-Werke, operating since 1895. Under this brand, it produces silicone and acrylic plasters, which have a high degree of efficiency, because the coating material does not require multi-layer coating on the surface. In this case, the Kaparol mixture has a stable color and is environmentally friendly, as it is composed of 2% solvents. For other manufacturers, this figure is 50%. The disadvantage is the high cost of plaster.

- LLC "Bolars". Russian company. Offers mineral plaster, characterized by elasticity, resistance to sunlight and temperature extremes. Bolars products are used even in areas with harsh climates.

Stucco wall surface finish

Simple instructions for applying to the surface from plaster manufacturers will help even an amateur to finish the walls with their own hands. Exception - walls with foam insulation, timber, chipboard and OSB.

Plaster coating the surface includes the following steps:

- The dry mixture is diluted in the right proportion with water. Then the composition is thoroughly mixed. After 15 minutes, the coating is laid on the surface.

- If necessary, the mixture is diluted with pigments.

- The composition is scooped with a spatula and laid out on the bottom edge of the trowel.

- The trowel is perpendicularly applied to the surface and when moving the angle decreases so that the tool is placed on the wall. The mixture is stretched over the surface without pressure. The composition is placed in one layer, with a thickness not exceeding the diameter of the filler fraction by 1.5 times.

- After covering the wall area of 1.5 square meters, the texture is overwritten with a grater.

- Points 3–5 are repeated until a complete decoration of the facade of the building is completed.

It is recommended that you work together. In this case, one person will apply the mixture, and the second will create a texture on the plastered surface area.

If multi-colored plaster is used to decorate the facade, then masking tape is glued to the border, due to which an even transition is created.

The better the wall surface is prepared, the easier and easier the finishing process is.

It takes at least 7 days for the leveling layer to completely dry out and gain strength. Only after that decorative colored plaster is applied to the facade.

The video in this article will help you understand the features of applying plaster.