Galvanized plaster grid

Galvanized plaster mesh - a material for surface reinforcement, which is used before applying the plaster. The product allows you to apply a thick layer of the product without the risk of peeling of the composition and increases the operational period of the finish.

The content of the article

Appointment

The galvanized grid for plaster is used for exterior decoration, since here the material is negatively affected by the environment, and the grid creates additional protection.

The product is also used for plastering surfaces indoors. The material facilitates the application of the solution, so even an inexperienced finisher is able to do it with his own hands.

Area of use

Galvanized metal plaster grid is used:

- when installing underfloor heating;

- for reinforcing a building base during decoration;

- to strengthen structures;

- to protect various mechanisms;

- for the construction of barriers and aviaries.

Material Functions

Galvanized plaster grid performs the following functions:

- Increases the strength of the plaster due to surface reinforcement. Metal strengthens the material and improves the resistance of the product to mechanical damage. It turns out a kind of reinforced concrete structure, which is able to withstand even increased load and tangible impacts.

- Binds the solution, preventing the formation of cracks and peeling, which increases the operational period of the finish.

- Increases adhesive properties of the material. The solution sets with the surface, as well as with the metal. The mesh holds the product and prevents plaster from collapsing.

- Allows to apply plaster on any surfaces with difficult geometry. The material does not always lie exactly in the shape of the building base. The grid accurately repeats all the bends of the surface, so the material also copies the geometric shape.

- Reduces material consumption. If you apply the material to a surface with irregularities and a large number of defects, then a large amount of agent will be required. In that case, if you pre-reinforce the construction base, then the flow rate decreases. The price of decoration, respectively, also becomes less.

- Allows to process any building basis. Thanks to the grid, the plaster adheres even to porous surfaces - polystyrene foam and other similar materials.

- Holds a large layer of plaster. A layer is applied to the grid, the thickness of which is up to five centimeters.

Product Types

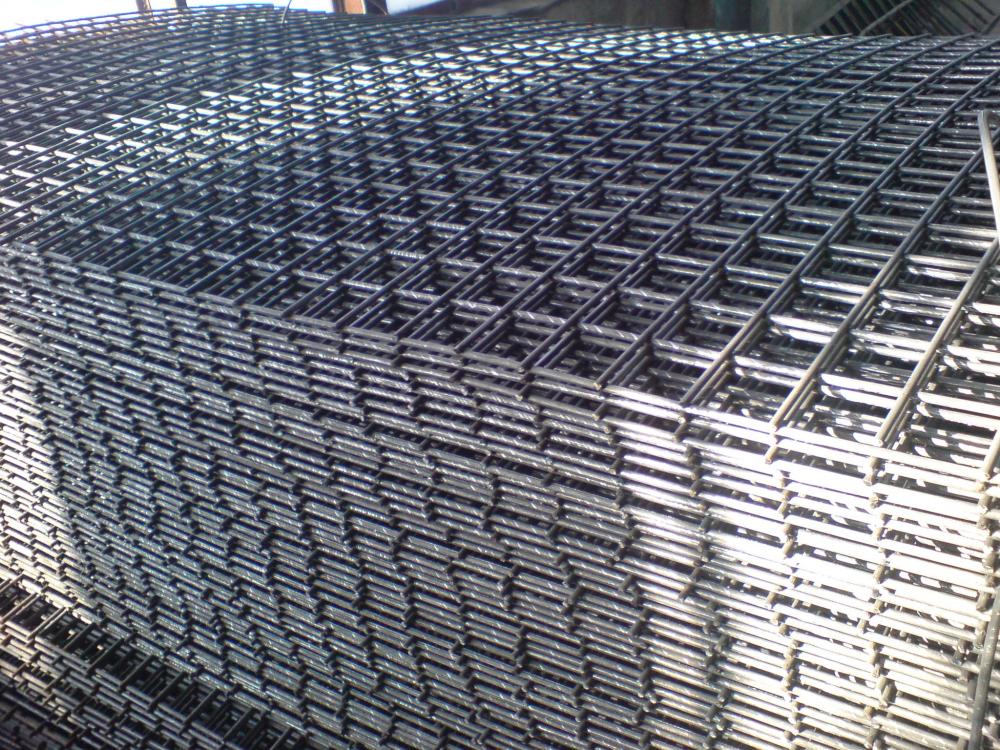

Plaster galvanized mesh has several varieties:

- Material made by hot dip galvanizing. The essence of the procedure is immersion of the product in hot zinc. Thanks to this, the product fills the smallest pores of the metal. The thickness of the zinc in this case is from 10 microns. The cost of such a product is more than the price of a similar product, but the quality of the mesh is higher. A distinctive feature is the presence of an influx of zinc on the wire.

- Galvanized plaster grid, which is made by electro-galvanic galvanizing. The essence of the procedure is that they have an electrolytic effect on a metal wire due to different poles. Zinc thickness - 3 microns. Externally, the product looks more attractive than the previous grid. The surface is smooth, shiny.Such material is cheaper than a hot dip galvanized wire, but the product is susceptible to corrosion due to abrasion of the protective layer, which leads to the appearance of rust on the finish within two years after repair.

Product Dimensions

Dimensions of galvanized mesh plaster:

- 1x1 cm;

- 2x2 cm;

- 3.2 x 3.2 cm;

- 4x4 cm;

- 5x5 cm;

- 10x10 cm;

- 15x15 cm.

How to choose the right one?

When choosing a galvanized plaster grid, pay attention to the joint seams of the wire. If dark spots are observed in this area, then this indicates the reconciliation of the product after galvanizing. Such fabrication of the mesh erases the zinc layer, which is why the material corrodes after plastering. As a result, rust emerges through the topcoat and this leads to the need for refinishing. For this reason, it is not recommended to choose such a product. The galvanized plaster grid should be smooth and without any stains. This guarantees a long operational period of decoration.

Surface Fixing Rules

The galvanized wire mesh for plastering has rules of use, which are recommended to be read before finishing.

Necessary materials and tools

To install the product you will need:

- galvanized wire mesh;

- dowels and screws;

- special galvanized mounting tape;

- drill.

Surface preparation

Before mounting the product, it is recommended to prepare the building base. The old coating is removed, after which the oily and greasy stains are removed. Next, the surface is cleaned of dust and dirt. After that proceed to the installation of the grid.

Product Preparation

Before fixing, the product is cut into pieces of the right size. It is not recommended to do this with a grinder, since such a tool contributes to the abrasion of zinc, which leads to the appearance of rust on the grid. Next, the material is treated with a solvent or acetone to degrease.

Mesh mounting

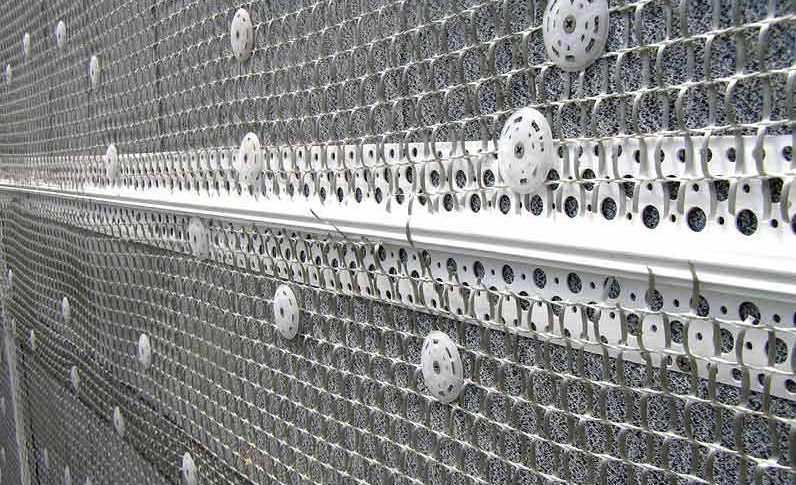

Mesh mounting algorithm:

- The instructions say that the installation of the product begins from the ceiling. In the building base with the help of a drill, holes are drilled into which dowels are inserted.

- Fasteners are mounted around the entire perimeter of the surface in a checkerboard pattern. The distance between the dowels is 30-50 cm.

- Under the head of the screw fixes a piece of galvanized tape.

- The mesh is fixed on the base by screwing it to the surface with screws, as in the photo below. The product should be as tight as possible so that there is no sagging. The grid is fixed with an overlap of ten centimeters on top of each other.

When the product is fixed on a building base, plastering is performed. The material is poured onto the surface with a special bucket. After that, the composition is distributed using the rule. Next, take a break to dry the product. Then the material is primed in two layers with a hardening break. Apply a second layer of plaster with a spatula. If after this part of the mesh appears through the composition, then do another treatment and so on until the product disappears under the plaster. After the material has dried, the surface is cleaned, dust removed and primed again. When the primer freezes, finish coating is performed.

The video in this article demonstrates how to properly fix the grid on a building foundation.

The use of a reinforcing mesh for plastering the surface is a necessary manipulation for finishing the facade and masking irregularities indoors. The main thing is to choose and use the product correctly.