Plaster grid: types of material

Any person, at least once, faced with plastering, heard about the reinforcing mesh, but not everyone knows how to work with it correctly, and why it is needed. In this article, we will try to answer these and many other questions as fully as possible, as well as find out what a plaster grid is and how it can not always be used under certain types of plasters.

The content of the article

What is the mesh for?

In fact, this is a very reasonable question, especially when you consider that the use of mesh with plaster has come into use relatively recently, and before such materials simply did not exist. Yes, in previous years the grid was not used, and that is why today we can observe cracked and dilapidated stucco facades (see How to strengthen the crumbling plaster with your own hands).

The fact is that almost any plaster has a natural shrinkage that takes place for many years, and if your wall has not lost its appearance in the very first years, this does not mean that this will continue. The building mesh for plaster holds the mixture in its original form, and does not allow it to crack as a result of natural shrinkage and mechanical damage, which, one way or another, are on any wall.

Previously, in order to plaster the walls of a new building, you had to wait several years until the walls shrink and take on a certain shape and structure. Now this problem simply does not exist, and this is thanks precisely to the plaster mesh.

It is impossible not to mention the strength characteristics of plastering using reinforcing mesh. Such walls are much more difficult to damage, and even if you suddenly need to redo the finish, there will be many difficulties with removing such old plaster (see How to remove old plaster from walls without problems).

Well, if we figured out the question of the need to use a stucco mesh, you need to talk about the materials from which it can be made, and there is a huge variety. You need to know all the details about the properties of each material, the only way you can make a truly high-quality and durable repair, which will not have to be redone the next year, and will not have to blush in front of guests coming to your house.

Choose material

In order to choose the right material from which the mesh will be made, you need to know all its features and understand the conditions under which it can be used. Each material has its own limitations on use, and some grids simply do not interact with certain stucco mixtures.

Metal

Metal is a strong and durable material from which things are designed to serve for a very long time, and plaster mesh is no exception. But in fact, this is far from the best choice, and such a grid has a number of limitations, but more on that below, but for now, let's consider varieties of metal mesh, and try to figure out which one is better.

Metal reinforcement is divided into three types:

- CPVS, or stucco perforated mesh. This material is made of sheet steel, on which the machine makes small cuts, after which it draws the sheet and the same mesh is obtained.Its main drawback can be considered a relatively large weight, such a grid creates a significant load on the surface, so it can only be used on walls built of durable materials, such as brick.

- Welded wire mesh. A mesh made of thin wires welded together perpendicular to each other. This material is much easier to work than its predecessor, and easier to work with. The mesh is easily attached to the facade and quickly takes the required shape. Another significant advantage of the welded mesh is the price, which is much lower than that of the glazed and even the netting, which will be discussed in the next paragraph.

- Rabitz. This material is better known as a mesh fence that encloses various objects. He did not have much aesthetic appeal, but as early as 10 years ago he simply had no alternative that could compete in price and quality. Of course, modern chain-link has undergone some technological changes, and now it is a completely different material, but the essence has remained the same, it is very difficult to work with it. Especially if you plan to do the repair yourself.

Important! Plastering on a chain-link grid is a laborious and complex process, so before you start it, we strongly recommend that you watch the video in this article, which clearly shows the entire process, and provides detailed instructions for working with this material.

So, to summarize, it can be noted that the metal mesh is more suitable for working with external walls, that is, in those places where a large and thick layer of plaster is required, and the maximum allowable load can afford the significant weight of the metal.

But not only in appearance the metal mesh is different. Until recently, its main disadvantage was susceptibility to corrosion, that is, with constant contact with water, the mesh quickly began to rust, and even a thick plaster layer could not protect it.

Sooner or later, rust appeared on the surface and left behind an unpleasant yellow spot (see. How to clean a wall of greasy stains: tips), which are almost impossible to remove subsequently. To eliminate this problem, manufacturers went to the trick, and began to produce a metal mesh that underwent additional processing.

So, today we can distinguish three main types of metal grids:

- Simple mesh without coating. For plastering, this material is used only in cases where there are no requirements for the decorative quality of the coating. In any other situation, it is better to refuse it in order to avoid problems in the future. The only advantage here is the low price, but given the fact that there is a possibility of reworking the entire repair, this nuance becomes completely irrelevant.

- Galvanized Mesh. The most popular and sought-after material among all metal grids. Here, all the wires are coated with a protective layer of zinc, which, as you know, is not susceptible to corrosion, and easily tolerates not only prolonged contact with water, but is also resistant to alkalis, which are present in excess in cement-based plaster mixes.

- Plastic coated mesh. Most often, it is used for the manufacture of fences and protections, since plastic itself does not tolerate contacts with alkali, which means that such a mesh cannot be used under cement plaster, which is most often used on facades.

Advice! When working with galvanized wire mesh, never use a grinder or other tool to cut or damage the coating. Subsequently, it is from this place that corrosion will begin to spread, which in a short time will destroy the entire grid.

Below we’ll talk in more detail about how to fill a metal stucco mesh onto a wall, but for now let's look at other materials that are more attractive in some situations and, as a consequence, are in demand.

Plastic

If you need high-quality stucco on a grid, then this is exactly what you need. Plastic is the cheapest material that most types of exposure are not afraid of. It easily tolerates contact with water and is able to quickly take the necessary shape after prolonged storage in wound form.

A significant disadvantage is the fact that the pvc grid for plaster does not tolerate contact with the alkali, which means it can not be used with cement mortars. Manufacturers are also aware of this, therefore they are developing new technologies that eliminate this lack of plastic. Such a stable grid costs much more, and other, less conscientious manufacturers use this fact to deceive customers.

To avoid this, do not rush to buy a whole roll, for a start just take a small piece, and place it for several days in an alkaline solution. At the end of the experiment, the mesh should fully preserve its qualities and appearance, in this case, the manufacturer can be trusted.

If you attacked low-quality plastic, then in two three days, it will completely dissolve in cement, and this is exactly what will happen to it under a layer of plaster. Simply put, the plastic mesh has two significant limitations on its use - it is cement plaster mixes and the thickness of the plaster layer.

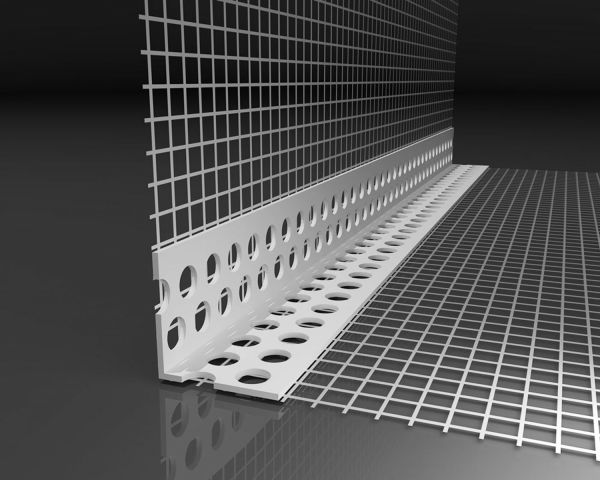

Plastic is less tensile than metal or composite. Therefore, it can only be used for interior walls. By the way, if you ever paid attention to a stucco profile with a mesh, you should have noticed that in this case it is made of plastic.

Important! Depending on the plaster mix and the thickness of the layer, the mesh size is also selected, the greater the load on the mesh, the thicker the wire and the larger the mesh should be.

Fiberglass

This material has a more scientific name - composite. That is, it means that several materials are involved in the manufacture, interconnected at the molecular level. Composite mesh is the most expensive of all the above, but its qualitative characteristics are much higher.

Fiberglass is not afraid of alkali, and easily tolerates even prolonged contact with water. It is practically impossible to dissolve in chemical solvents, and the tensile strength is comparable to metal. It is distinguished from metal by its lighter weight, which allows you to work even on lightweight facades, without fear of creating an excessive load on them.

By the way, composite mesh is often used as protective structures on scaffolding. Surely you have met objects under construction, covered with a mesh, and so here it is made of fiberglass. The protective mesh is designed to hold accidentally dropped construction debris, and in addition, it can protect a person from falling, as it can easily withstand its weight.

It is very simple to lay a fiberglass plaster grid, it does not have shape memory, so even after very long storage in rolls, it is easily straightened and attached to the wall in any way possible.Another interesting feature of composite fiberglass is the complete absence of thermal expansion, which is why swimming pools are made of this material today, which during the summer heat do not deform under the scorching sun.

You can use such a grid both indoors and outdoors, and the only limitation is the correct selection of mesh size and the reliability of fastening. If all of a sudden, your plaster begins to lag behind the base, remember, it’s not the grid, but how you fixed it.

A few words about the installation

The quality of the finish largely depends on the quality of installation. The reinforcing mesh should act as a protective structure to prevent the plaster layer from cracking during natural shrinkage or deformation, for some reason. If the grid is not securely fixed and there are sagging, then there will be no sense from it, therefore, this attention should be paid especially close attention.

The stucco mesh can be fixed in two ways:

- On special glue. This method is only suitable for lightweight materials, and in the case when the thickness of the plaster layer does not exceed 30 millimeters.

- On anchor or dowel. This method is suitable for mounting metal and steel plaster mesh and in the case when the thickness of the plaster layer exceeds 30 millimeters.

The mounting method is chosen independently, and the main rule here is to achieve maximum strength, therefore, the heavier the mesh, the more often it needs to be fixed. As a rule, plastic or composite nets are fixed on the adhesive, as well as a plaster profile with a mesh, which must also be tightly fixed.

The glue is applied to the wall, after which the mesh is immersed in it, and now it needs to be allowed to dry well, and only after that you can start the process of applying the plaster mixture.

If you use a netting netting, or even more so CPVS, then you cannot do with one glue here, and you will have to drill the wall and hammer the dowels into it. The more often they are installed, the better, but 20-30 centimeters in all directions is considered the optimal size for mounting.

What to use, dowels or anchor bolts, depends on the material from which the walls are built. Dowels are good for holding in dense materials, such as ceramic bricks, but anchors are suitable for working with hollow materials, such as expanded clay concrete, or lightweight materials, such as aerated concrete.

The most important thing here is to drill a hole of exactly the depth that is needed, you can do it a little more, but in no case no less, since in this case the bolt just rests and it will be very difficult or even impossible to pull it back.