Plaster consumption per 1 m2

Gypsum plaster is a generalized name for a group of finishing materials, which include natural gypsum and polymer additives. Polymers are responsible for the elasticity of the building mixture and hardness of the coating, and gypsum for the appearance. The material is used for rough finishing as a basis for wallpaper and ceramic tiles. Also, after drying, gypsum plaster acquires an aesthetic appearance of the finish coating, forming either a smooth surface or a relief pattern. Therefore, additional decoration is not required if it is not provided for in the project.

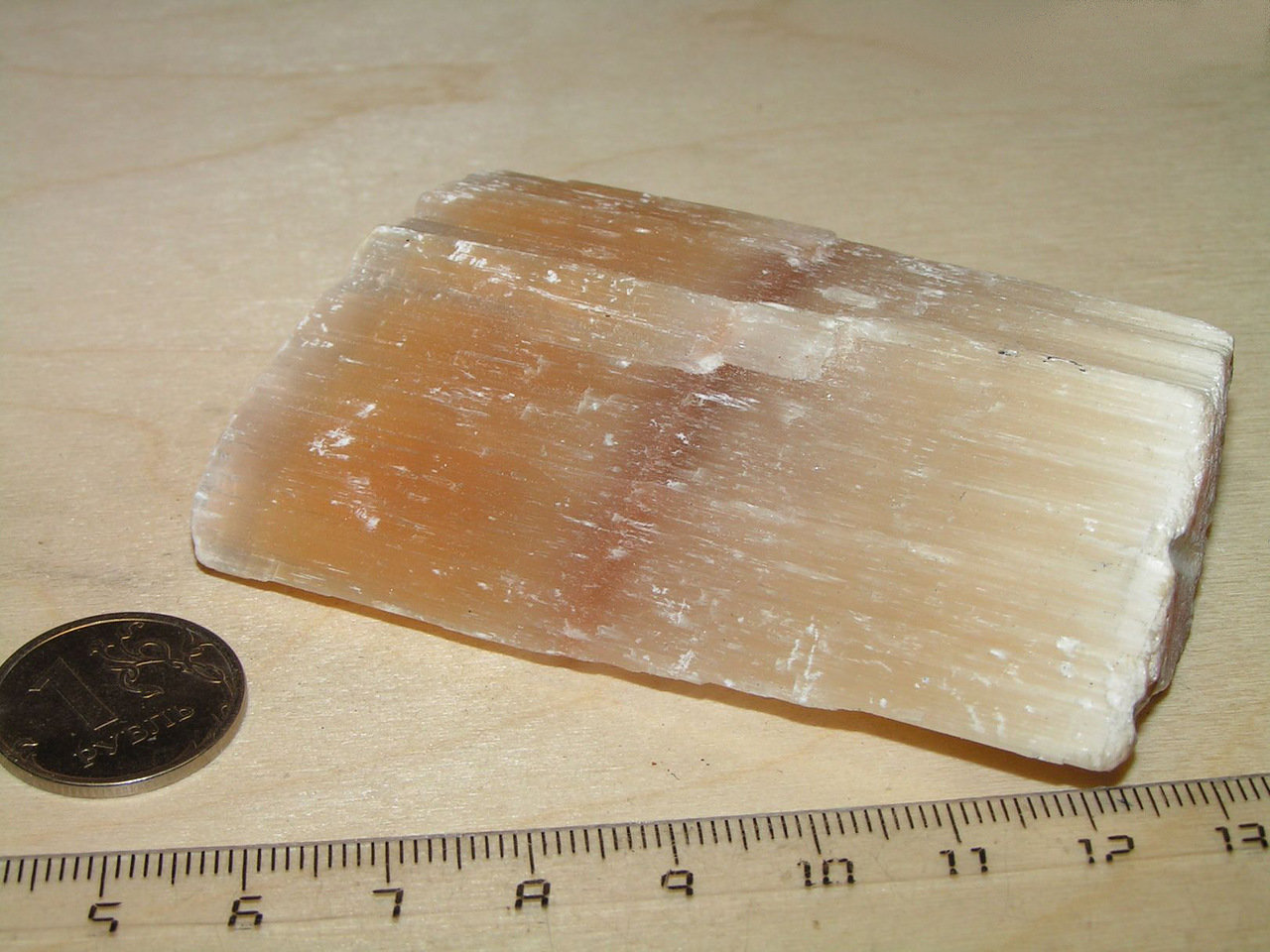

Gypsum is a mineral that belongs to the class of sulfates. In nature, there are two varieties: selenite and alabaster. Selenite has a fibrous structure, alabaster has a granular structure, but the chemical composition is the same. Both minerals are used as ornamental stones.

Gypsum powder as the basis of gypsum plaster is obtained by roasting selenite and alabaster. The calcined minerals are ground to a finely divided state. The smaller the gypsum particles, the more plastic the building mixture.

In addition to gypsum, the mixture contains natural or artificial fillers and polymer additives. Fillers reduce the consumption of mineral powder and increase the strength of the coating. And polymer components improve the physical properties of the plaster: increase adhesion and ductility. The price of the building mixture is formed taking into account the composition. Instructions and material consumption per 1m2 are indicated on the back of the package. When the required flow rate is calculated, gypsum plaster acquired taking into account the specific task and condition of the walls.

Physical properties

The physical properties of gypsum affect the scope of plasters. Gypsum hydrophilen: easily interacts with water and is destroyed by exposure to excess moisture. Therefore, gypsum plasters can not be used in wet rooms, the area of application is the decoration of dry rooms. In this case, gypsum plaster should not directly come into contact with metal, for example, with reinforcement.

Due to the ability of gypsum to absorb moisture, contact with metal parts leads to corrosion of the metal.

Gypsum plaster - adhesive material: adheres to the surface of the substrate at the molecular level. With proper use, the gypsum plaster coating is strong, despite the relative fragility of the material.

Operational characteristics

- Environmental friendliness (95% consists of natural materials).

- The time required for the drying of a layer of 10 mm, on average - 4-7 days. For comparison: a cement-sand mixture coating dries for 4 weeks.

- It forms an even coating that does not require additional finishing.

- The material is plastic: gypsum plaster is also used to create a relief wall decor.

- It forms a solid base for wallpaper, tiles and stains.

- Gypsum plaster is adhesive: adheres firmly to the base.

- The material does not shrink and does not crack.

- The coating is vapor permeable; no condensation forms under the plaster layer.

- Gypsum plaster does not burn even when exposed to open flame.

Decorative qualities

Walls decorated with gypsum plaster are painted, polished, and covered with a relief pattern.

Gypsum plaster: consumption per m2

To calculate the consumption of gypsum plaster per 1 m2, consider two indicators: the condition of the walls and the thickness of the applied layer. On a flat surface, the consumption of dry mix will average 300 g per m2 with a layer thickness of 1 mm. In case of blockage (height difference) exceeding 5 mm, the leveling layer will increase in thickness. Planning to do it yourself, get acquainted with the calculation algorithm or use the calculator online by entering a request for gypsum plaster consumption per 1 m2.

Consider a specific example.

1. Given: a wall area of 1 m2 with a blockage of 40 mm.

2. Using a plumb line, we outline the vertical and measure the depth of the blockage at least in three points: the more measurements, the more accurate the calculations.

3. We get the results: in the first point, the blockage is 0 mm, in the second - 20 mm, in the third - 40 mm.

4. Add up the numbers and get a value of 60 mm.

5. The result is divided by the number of measurements (3). We get an average block depth of 20 mm: this is the thickness of the plaster layer, which will be required to level the surface.

6. Next, multiply the thickness of 20 mm by 300 g (the weight of the gypsum mixture, which is needed for the plaster layer with a thickness of 1 mm and an area of 1 m2). We get a preliminary result: 6 kg of dry mix per 1 m2.

7. We take into account the finish layer with a thickness of 3 mm: it will require another 0.9 kg of the mixture.

8. To the resulting 6.9 kg we add 10% for an unforeseen event.

9. The resulting amount is rounded up to a larger value.

10. Result: for a building mix gypsum plaster, the consumption per 1 m2 will be 8 kg.

Of course, these are average figures. For each brand, manufacturer recommendations have been developed. Take this into account when calculating the characteristics - gypsum plaster consumption per m2. For example, with a layer thickness of 10 mm, a mixture of Volma gypsum plaster uses an average consumption of 8-9 kg per square meter, and Teplon gypsum plasters have a consumption of 9 kg per m2 under similar conditions.

The recommended minimum layer thickness for the building mixture of these grades is 5-50 mm, (Teplon) and 5-60 mm (Volma). If additional layers are required, then this is done only after the previous layer has completely dried.

Features of working with gypsum mortar

The gypsum mixture in the form of a powder is diluted with water. Given the short viability of the solution, prepare the composition in small portions. The term "viability" means the period of time during which the solution retains plasticity. Before preparing the next batch of plaster, thoroughly clean the container.

To correctly calculate the consumption of gypsum plaster determine the specific purpose. For example, a thick solution is prepared to seal defects in the form of chips and cracks. Finishing requires a fluid elastic mass of plaster, which is easily distributed over the surface.

In the video in this article - a master class on applying gypsum plaster with a description of the stages.

With a competent approach to the choice of building mixture and preliminary calculations, gypsum plaster is a functional and economical finishing material, which builders like to work with and even lay people cope with.