Bark beetle plaster: consumption

A special place in the category of decorative finishing materials is occupied by “Bark beetle”. Plaster, the consumption of which is indicated on the packaging, is sold in the form of a dry mixture or paste. A ready-made mortar is more convenient for DIY repair, but the price of the paste is higher than the powder mixture. Therefore, in order to save money, novice masters buy dry plaster and independently mix the mixture for application to the walls. In order to get a decent result and not overpay the extra money, calculate exactly what consumption of Bark beetle plaster will be needed just for your purposes.

The content of the article

How is bark beetle plaster consumption calculated per 1 sq. M

First take measurements of the walls and calculate the working surface area, plan the sequence of decoration. If you ennoble the facade, buy material with large granules ranging in size from 2.5 to 3.5 mm. For internal work, use plaster with small fractions of minerals from 0.8 to 2.5 mm. Manufacturers indicate consumption rates in the instructions, but the amount of mixture for a specific amount of work at the facility is determined individually.

What affects the flow

The increase or decrease in the expenditure rate is affected by:

- surface condition, the degree of preparation for plastering;

- grain size of the mineral filler;

- component composition of the mixture (acrylic, silicate, silicone base);

- type of plaster (finished paste or powder);

- surface type (internal wall or building facade);

- plaster layer thickness;

- wall curvature;

- technique of applying material to the surface.

For correct calculations, sketch and designate the dimensions of the surfaces with all piers. To calculate the right amount of material, multiply the wall area by the consumption rate for one square meter of surface.

Consumption rates from manufacturers

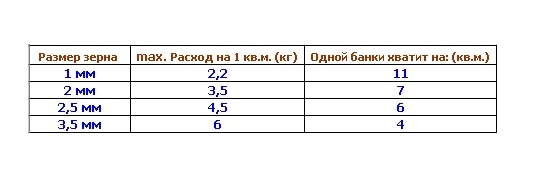

Examine the labeling on the factory packaging, pellet size information, and find out the recommended recipe consumption. Bark beetle plaster is produced at different plants, and manufacturers give their own recommendations on the ratio of water to dry mix, on consumption per square meter of surface. The average typical indicator is 2.5-4 kg. Examples of individual brand recommendations:

- stucco bark beetle. Consumption per 1 m² of Volma brand mix - 6.5 kg;

- stucco bark beetle. Expense on m² mixes of the Prospectors brand - 9 kg;

- silicate mix Ceresite with a granule size of 2 mm - 3 kg per 1 m²;

- Ceresit silicate mix with a diameter of granules of 3 mm - 4.5 kg per 1 m²;

- polymer-cement mixture Ceresite with a fraction size of 2.5 mm - 3 kg per 1 m²;

- polymer-cement mixture Ceresite with a fraction size of 3.5 mm - 4 kg per 1 m²;

- Ceresit silicone paste with 2 mm granules - 3.5 kg per 1 m²;

- Ceresit silicone mixture with fractions greater than 2 mm in diameter - 4.5 kg per 1 m²;

- acrylic plaster Ceresit - 3 kg per m²;

- Knauf Rotband facade plaster - 8.5 kg per 1 m².

Indirect factors also influence the consumption of Bark beetle: qualification of the plasterer, storage conditions of the powder in the warehouse, humidity level and room temperature during plastering.

Important! Buy mixtures from trusted and reliable suppliers, choose worthy and serious brands. Ask sellers for certificates of quality and compliance with building standards. Production mixtures of dubious little-known manufacturers do not guarantee economical consumption and quality of finishing operations.

Important! When purchasing finishing materials, add 10% to the calculated indicator of the required quantity and purchase a mixture with a margin.

Calculation Examples

1 example

You have to finish the surface of the wall with an area of 10 m². As the material you have chosen the brand of dry mix KnaufRotband. The concrete base falls 50 mm. A level check revealed wall deviations of 6, 4 and 2 cm at three points. Beacons are installed in three places on a plane. We summarize these indicators and divide by 3 the result obtained to obtain the thickness of the plaster layer. In this case, the thickness is 4 centimeters. On the packaging of the Rotband mixture, it is indicated that 8.5 kg of dry mixture with a layer thickness of 1 cm is required per square meter of wall.

Due to the slope of the wall, the plaster needs to be laid with a layer of 4 cm. 8.5 kg x 4 cm = 34 kg. A ten square square wall will take 10 times more, that is 340 kg. Add 10% of the planned stock and get 374 kg. Knauf merchandise packaging - paper bags weighing 30 kg. For wall decoration with an area of 10 square meters. m will need 13 bags.

2 example

Factory packaging of Ceresit, which sells 25 kg Bark beetle plaster. The material consumption is to be calculated for surface treatment with an area of 30 square meters. Marking of the dry mixture - ST-35, grain with a diameter of 3.5 mm. The basis is drywall with a primer. On 1 m², the manufacturer recommends using 4 kg of the mixture. Large granules and a flat surface make it possible to apply a layer of plaster with a thickness of not more than 1 cm. 120 kg of dry mix + 10% of the reserve, that is 132 kg, is consumed per 30 square meters of the wall. For finishing, 6 bags are enough.

How to save expense

Active absorption and the porous structure of the base increase the consumption of decorative plasters. Thorough preliminary preparation of the surface, leveling and coating with an insulating primer will help save material consumption. Moisture from the solution on the treated base does not absorb into the surface and does not weaken the decorative layer, adhesion will increase. The primer composition will reduce the destructive effect of temperature and humidity differences, strengthen the bearing layer. This will protect against possible peeling of decorative plaster and reduce material consumption.

Important! Take as many measurements as possible at different points on uneven walls. Choose problem areas, accurately calculate the depth of coverage, mark the area and install beacons in the places of the deepest dips. Measurement accuracy directly depends on the number of measurements.

The measurement results are arithmetically added and divided by their number. The height of the beacon is added to the result. A separate calculation of the thickness of the plaster layer is performed for each surface.

It is advantageous to form strongly curved and littered walls with plasterboard and treat with a coating primer based on cement and insulating components of deep penetration.

Video

Photos and videos in this article will help you get acquainted with the method of calculating the amount of material for beginning plasters.