Cement plaster

Cement plaster - a material for roughing. This tool creates the basis for the application of putty and topcoat. For this reason, the result of the finish depends on the quality of the putty. To ensure that the result is satisfactory, it is recommended that you familiarize yourself with the features of the material and the rules for working with the solution.

The content of the article

Types of cement plasters

Cement-based plastering is of two types: cement-sand and cement-lime. Materials differ from each other in composition and some characteristics.

Cement-sand composition

The main substance of the material is cement. Such a product is marked M150 - M500. This is not to say which cement is better for plaster, since the type of material depends on the nature of the finish. For the facade, it is recommended to use tools from M300 and above. For the interior of the building, material M150 or M200 is suitable.

The second element of the plaster is sand. Such a product provides strength after drying. Manufacturers use quarry or river sand as part of the product. 3-4 parts of the component are taken on 1 part of cement. However, the ratio of products is changed if it is necessary to increase the strength of the material.

For rough plaster, sand grains of medium dimensions are added to the composition. Coarse material is used only for the product, which is used for rough decoration of the facade, when you can not achieve a flat surface. Fine grains of sand are added to the composition of the decorative product.

Plaster of cement and sand in addition to these components contains additional components. Such products are added to the composition to increase strength, elasticity, drying speed and operational period.

Cement-sand plaster has frost resistance, moisture resistance and resistance to temperature changes. This allows you to use the material for plastering the facade, in unheated rooms, as well as in rooms with high humidity.

The sand based product also has several varieties.

Simple stuff

The product is applied to a building base without the use of guides. Double processing is carried out - spray and soil. The overlay in this case is not done. Simple material is used in rooms where the appearance of the decoration is unimportant - in the back rooms, in warehouses, in the garage, cellar and so on. The meaning of plastering is masking defects and protecting the building base from mold and bending.

Superior product

This sand and cement plaster is applied in several layers - spray, soil and cover. After solidification of the latter, the surface is wiped with an industrial grater. This plaster is in the greatest demand. The product is used to decorate the facade, as well as inside the building. Including in rooms with high humidity.

High quality composition

This is a luxury cement plaster. Such material is applied along the guides. Processing is done in 5 layers - spray, 3 soil and covering. This application method is performed where a high-quality finish with a smooth surface is required.

Cement-lime remedy

Product components are cement and slaked lime. The product has increased strength and vapor permeability.

In addition to the main components, the product also contains sand, polypropylene fiber and moisture-retaining elements. The material is suitable for manual and machine application. The tool has two forms of release - the finished product and dry formulations. The material is used for interior and exterior decoration.

Product Advantages:

- suitable for any type of base;

- good adhesion, which facilitates the application of the material;

- the composition includes antibacterial substances that prevent the occurrence of mold and fungus;

- easy to apply;

- increased resistance to mechanical stress.

Cons of the material:

- reduced compressive and tensile strength;

- high price compared with cement-sand composition.

Areas of use

It is important to know not only how to plaster with cement, but also for what areas the material is used:

- for facade decoration;

- for plastering walls and ceilings in rooms with high humidity - pools, bathrooms and others;

- in dry rooms and corridors;

- in unheated rooms - a garage, a warehouse, a cellar, a barn and so on;

- for closing cracks and other defects of the building base;

- for leveling the surface with differences;

- under the tiling of the base.

Specifications

Material Specifications:

- compressive strength - 6-12 MPa;

- adhesion to separation - 0.3-0.4 MPA;

- the shade of the product before and after cooking is gray;

- recommended layer thickness - 5 mm;

- maximum layer thickness - 4 cm;

- liquid flow rate for preparing 1 kg of dry mixture - 150-400 ml;

- the viability of the finished product is from 30 minutes to 6 hours, while the duration of solidification is affected by the presence of lime in the composition;

- frost resistance - 50 cycles of freezing / thawing;

- conditions of use - air temperature from +5 to +300WITH;

- the next stage of finishing after plastering - after 2 weeks, if painting or puttying is performed;

- Tiling - 3 days after the material dries;

- expiration date - 12 months;

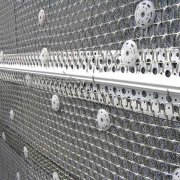

- when applying the material, surface reinforcement is performed.

Consumption per 1 m2

Material consumption depends on surface condition. The more differences and defects, the more funds will be needed to mask imperfections. The standard consumption of cement plaster is 17 kg per 1 m2 with a layer thickness of 10 mm.

Popular manufacturers

Cement plaster is produced by many manufacturers, but professionals recommend giving preference only to popular brands, as they guarantee the quality of products. Masters recommend the following brands:

- Plaster cement Knauf. The product line includes both simple materials and high-quality ones with the addition of components that improve the properties of the material. All means increase the thermal insulation of the building, do not crack after hardening and provide vapor barrier to the surface. The cost is in the range from 200 to 280 rubles for a package weighing 25 kg.

- Stucco from the company Ceresit. The line of tools also has simple and complex materials. All products have vapor permeability and resistance to negative environmental effects. The cost is in the range - 330-1200 rubles per 25 kg of product.

- Plaster cement Axton. The products of this company are distinguished by strength, durability, high quality, versatility and ease of use. The average cost is 510 rubles per 25 kg.

- Material Volma. The company produces three types of cement-based plaster - Aquasloy, Aquaplast and Plinth. Each of these types is supplemented with components that improve the properties of the material. Means are used for exterior and interior decoration.The price is in the range of 200-250 rubles per 25 kg.

Self-preparation

Material does not have to be purchased ready-made. Cement plaster is made by hand. There are two recipes for preparing the product:

- Product based on cement and sand. The ratio of components: 3: 1. Sand is sieved through a metal sieve and mixed with cement. Next, water is added to the cement plaster mix and the solution is kneaded using an industrial mixer. To increase the plasticity of the product, PVA glue is added to the product. The ratio is 100 ml of glue per 10 liters of solution.

- Product based on cement and lime. In this case, 1 kg of lime will be required. The product is placed in a metal bucket and 2 liters of water are added. When the product cools, the material is passed through a fine mesh sieve. After this, the product is left for 2 weeks. Next, sand and cement are added to the product. The solution is kneaded with an industrial mixer or drill with a mixer nozzle until the consistency of thick sour cream.

Application technique

When using cement plaster, it is important to observe the technique of using the material.

Wall preparation

- Remove the old coating (as in the photo below). Next, degrease the surface. All oil stains impair the adhesion of the plaster to the building base, therefore it is recommended that they be treated with a solvent or other similar means.

- Check the base for unstable fragments. If any are found, remove them, and prime the area of the defect and seal with a solution.

- Anticorrosive process all metal elements that failed to dismantle. To protect the surface from mold and mildew, use a special composition. If a primer with antiseptic properties is used further, ignore this step.

- Apply a primer to the building base. It is recommended to perform double processing with a break for drying.

Necessary materials and tools

For plastering you will need:

- solution;

- special bucket for applying the product;

- putty knife;

- trowel;

- ironer;

- grater and industrial grater;

- an industrial mixer or other similar tool;

- a clean bucket;

- falcon for plaster.

Cooking material

Instructions for preparing the solution are indicated on the packaging. According to the recommendations, combine the water and the dry mixture and knead the material to a homogeneous solution without lumps, using an industrial mixer or other similar tool. Leave the product for 5-10 minutes and stir again.

Application of the composition

Plastering technique:

- The first layer is spray. Throw the material onto the surface with a bucket and level it with the rule. Use a liquid solution for this, but the product must not drain off the wall.

- The second layer is soil. In this case, a thick sour cream consistency solution is used. Put the material on the falcons, apply the product to the surface with a trowel. Pause the finish for half an hour. Then level the product using the rule. If defects appear in the process, fill in the imperfections with the solution.

- The third layer is covering. For this application use a solution of liquid consistency. After treating the base with this material, take a break to dry the product. Then clean the surface with an industrial grater and apply two primer layers with a break for drying.

- Cement plaster putty is used. Such material helps to completely level the surface. Apply with a wide spatula, allow to dry and grate. Surface finish with a primer. It is recommended to apply two layers and after each treatment take a break to dry the composition. Then decorate the surface.

Decorative cement material

A cement-based product is not only used for roughing. There is a special tool that is used to decorate the base. Cement decorative plaster creates an original texture on the surface. The composition is supplemented with pebbles and pigments, due to which the tool acquires an unusual texture.

Decorative cement plaster is durable and moisture resistant. The material is used for finishing the facade. Decorative cement plaster is also used in rooms with high humidity - shower rooms, pools, bathrooms and others. The product is applied to the surface with a spatula and left to dry.

The video in this article shows how to properly use cement plaster.