Putty for exterior work: material for leveling the walls

Puttying is one of the technological operations of the plastering process - this is the finishing leveling of the finished base screed. To level the wall directly, use a composition with a coarser dispersion called start plaster.

It creates a durable coating, but has one drawback - a rough surface. Make it as smooth as possible when preparing the walls for painting, and putty is called for.

You will learn how this is done by watching the video in this article, during which you will be offered many other useful information.

The content of the article

Facade putties

Putty, as such, is not the prerogative of facade work. It is necessary to use this material not only outside, but also inside the building - when preparing walls and ceilings for finish finish.

So:

- The difference is that for the interiors, in any case, residential, use gypsum-based compounds, and for the facades cement plasters are needed, since they have the necessary moisture resistance. Cement in them is a cementitious base, and mineral and polymer additives improve performance.

- This is an incredible plasticity, resistance to low and high temperatures, as well as to ultraviolet light, which is able to spoil a beautiful decorative coating even faster than moisture. To prevent this from happening, facade paints must also be resistant to sunlight.

- By the way, there are even colored putties that can be matched to the paint. In principle, today they produce not only highlighted putties, but also primers. The price of pigmented compositions is slightly higher, but it is compensated by the fact that when they are used, the coating gets a more saturated shade, and practically does not fade.

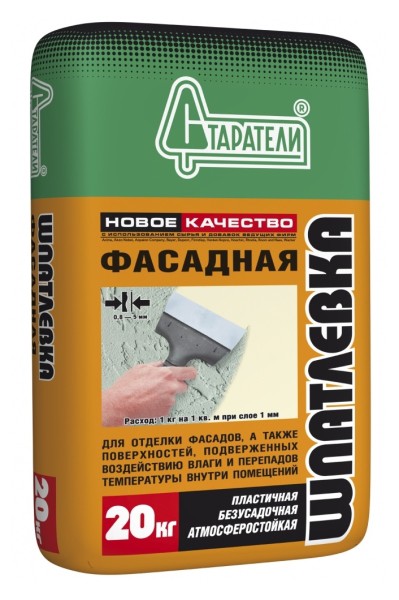

Facade putties are produced, both in the form of a paste, ready to use, and in the form of a dry mixture, which is diluted with water immediately before application to the wall. The ratio of dry to liquid component varies, depending on the type of putty. It is usually regulated by the manufacturer’s instructions on the product packaging.

Varieties of mixtures

There are several types of facade putties, differing mainly in component composition. The cheapest are cement putties that do not contain polymer resins.

Such compositions are not very elastic, and, accordingly, it does not matter to smooth out surface roughness. Therefore, when using them, at least three layers are applied.

So:

- The most popular leveling compound additives are acrylic resin and latex. They significantly improve the characteristics of cement and gypsum compositions, making them practically universal.

- They are applied in the thinnest layers, which allows to achieve maximum smoothness of the surface being leveled. Either one of these components can be added to the plaster composition, or both - such options are called acrylate.

- Putties, which are called polymer, have a multicomponent composition. In addition to acrylic, they add polyurethane, as well as epoxy. They have excellent strength and resistance to weathering.

- The main thing is an unusually high adhesion to various surfaces, which allows you to putty not only on the base screed, but also on any other basis: brick, concrete: both heavy and cellular, wood, and even insulation.

- Silicone based putties have the same advantages. They are truly universal, and are applied both as a starting layer and for finishing leveling.

- Cement-polymer pastes are also used as repair compounds - for sealing joints between plates, deep cracks in concrete. Such screeds are not even afraid of mechanical stress, not like water or ultraviolet radiation.

High cost is perhaps the only drawback of polymer putties. But, they are very economical: due to the high ductility, the layer thickness can be no more than 1 mm.

How to plaster a facade on a heater

Plastering a concrete wall or brickwork is traditional type of facade decoration. In most regions, with the possible exception of the southern ones, where there is practically no frost, houses need to be insulated.

Their owners prefer to do this outside - so as not to reduce the area of the premises. And yet, from the outside you can use any heat-insulating material, even polymeric, which is unacceptable for a living room. Therefore, at one time, the technology of plastering walls on insulation was developed.

Universal putties - this is the best option for such a finish. So we want to tell how to plaster the walls using insulation with our own hands.

Installation of insulation and mesh

As a heater for plaster, most often use polystyrene foam boards. You can, of course, take mineral wool, but it should be remembered that its service life is less, and the density is lower.

As for polystyrene, the density indicators of this material vary. For plastering, you need to use slabs with a brand name not lower than PPS-25.

So:

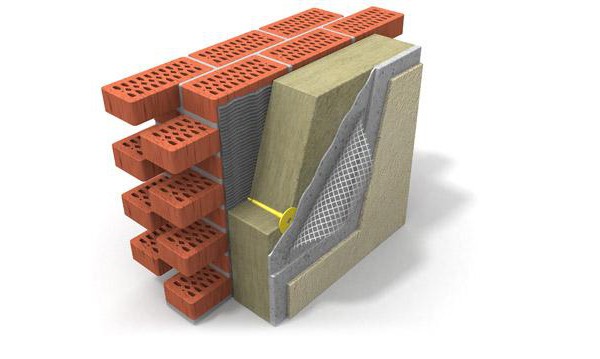

- In the photo above you can see the sequence of work when plastering the insulated facade wall. First, it is primed (seePrimer walls and all for that matter), since expanded polystyrene boards are mounted on glue. In addition, they are additionally fixed with dowels with a flat hat.

- In order for the putty to be able to stay on the insulation, its surface is pasted over with fiberglass stucco. It not only promotes good adhesion of the screed applied, but also makes the base more rigid. No special glue is required for the mesh - it is glued directly to the working plaster mix.

- Such solutions do an excellent job with the glue, as there is an epoxy resin in the polymer putty. Only when buying material you need to make sure that you have taken exactly what you need.

- Thus, a solution layer is first applied to the insulation surface. Until he grasps, the net is glued, and only then finish alignment is made. The reinforcing layer will then be between the two screeds.

- The mesh is glued, starting from the corner zones: a piece of canvas 30 cm wide is folded in half and applied to the wall so that the bending point coincides with the edge of the corner, and the sides are applied to the walls, and, smoothing, slightly pressed into the wet solution.

- During installation, it is cut into small pieces of 1.5-2 m, since putty is carried out in separate sections. Otherwise, the screed will seize and the net will not stick.

The main thing is that there are no damaged areas or adhering debris on the surface. If necessary, it is better to replace one slab than torment it later, trying to hide a damaged place under a layer of plaster.

Putty application

Before proceeding to finish leveling, you need to wait for the starting layer to solidify. Half an hour is usually enough.

In order not to spend much time, it is easier to do this:

- Break the wall into small grips, and starting from the corner, start plastering and stick the grid on the first square. Next, take on the second section, and while it dries, return to the first, and putty it.

- Having finished, you begin to plaster the third grab, and after mounting the grid, return to the second - and so on, until you reach the opposite corner. Do not forget to glue the joints of the reinforcing tightly.

When the grid is mounted over the entire wall, and, accordingly, the first leveling layer is applied, it is necessary, after waiting for it to completely harden, to finish puttying with subsequent sanding. Then it remains only to remove the dust and prime the screed before painting.