How to putty walls correctly: instructions

How to putty plastered walls? To get a flat and sufficiently smooth surface, it is necessary to correctly perform its primer and putty.

Puttying is a fairly simple task. In this case, the basic rules are adherence to the process technology and the ability to use construction tools correctly. This article proposes to get acquainted, how to putty the walls correctly?

The content of the article

Features putty for walls

In its composition, putty is:

- Gypsum(cm.Gypsum putty: its advantages and problems of use) Such a material has a low price, perfectly levels the surface, and has no shrinkage. The disadvantage is poor coating stability when exposed to moisture, which limits its scope.

- Polymer or acrylic. Main advantages:

- excellent moisture resistance;

- absolutely does not shrink;

- with its help, a high surface quality is obtained.

The only drawback is the high price.

- Cement(cm.Cement-based Putty: Material Features) It is characterized by increased moisture resistance, but has a high shrinkage rate.

Purpose of putty

By purpose, putty can be:

- Starting - leveling. This mixture has:

- increased strength;

- excellent adhesion;

- large grain size.

The thickness of the material from 2 to 19 millimeters. Used after applying plaster to level the walls.

To improve the quality of the puttied walls, a special paint net is mounted, and already on it evenly throughout the plane, the putty mixture is distributed. In this case, it is applied in a continuous layer. The advantage of this technology is the high-quality placement of the solution on the surface.

- Lighthouse. Solutions from starting putty do not differ. The difference lies in the use of beacons, which are a rail made of:

- a tree;

- gypsum;

- metal.

The element is set strictly vertically, which is checked by the building level. On the wall, the lighthouses are fixed with a gypsum mixture, which dries quickly, and you can perform puttying. In the same way, horizontal alignment occurs, which is checked by the rule. Due to the high cost, this technology is rarely used.

- Decorative or finish (cm.Finishing putty: how to apply qualitatively) It is applied when performing decorative finishes. With its help, it is easy to get a surface quite even and smooth, hide small defects. The strength of the mixture is less than the starting, processing it does not cause great difficulties. When applied, the layer is made up to four millimeters thick.

- Universal. Combines the properties of the two previous mixtures. Its cost is higher, and according to the characteristics, the coating is slightly worse than the finishing and starting putties. It is recommended to take when decorating the walls, without large flaws.

Manufacturers produce putties:

- Dry. Such materials have a low cost and a long shelf life.

- Ready to use. They are convenient to use. You do not need to use a mixer to prepare a homogeneous putty mixture, which saves time and there is practically no dust. But their cost is much more than dry. They have a relatively short shelf life.

Tip: Finished formulations give great shrinkage.When applying a layer up to two millimeters thick, they cannot be used.

What tools are needed for applying putty

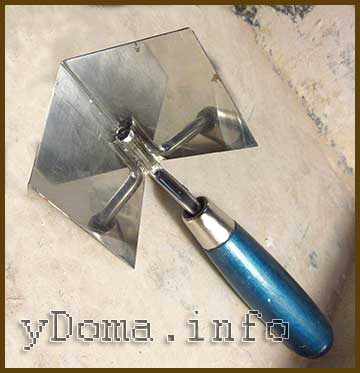

To putty the walls of the room with your own hands, it is necessary, first of all, to purchase a minimum set of necessary tools. An example of them is shown in the photo.

To work, you will need:

- Electric drill, with a special nozzle - mixer. The dry mixture can ideally be stirred only with a special mixer, after which it should end up with a homogeneous, lump-free putty.

- Set of different sized spatulas. It is convenient to use a large tool, but in hard-to-reach places they will not be able to qualitatively putty the wall.

- Rollers and brushes for priming walls.

Tip: Do not skip the priming step. After such a coating, a thinnest film forms on the wall, which further increases the strength of the structure and provides better adhesion or adhesion of the treated surface to any materials for cladding.

The rule. It is used in case of unevenness on the walls, and putty must be applied with a sufficiently thick layer.

- Building level. It can be alcohol or laser. In case of irregularities on the wall before the start of puttying, test beacons are mounted, which are level-controlled.

- Sandpaper. To make a beautiful surface, a fine skin should be used when rubbing. An ideal result will allow you to get a grout with the 240th sandpaper. The smallest skin is used only for finishing putty. Coarse coarse sandpaper is taken to grout the wall at the starting initial putty stage.

- Hand skinner. The tool facilitates the surface grouting process.

- Container for stirring the mixture.

How to prepare the walls for putty

You can get a good result only after a quality wall preparation, which cannot be achieved without putty. This is especially important when used as a wall coating of paint. All flaws will be visible under the wallpaper.

Before you properly putty the walls, they must be prepared:

- Perform dust cleaning, remove old coatings, scale and other impurities.

- Degrease. This will improve adhesion. In this case, the wall can be washed with compounds that contain alkali.

- Perform thermal and antibacterial treatment. Rust is cleaned with a burner, and with increased humidity in the room, to prevent mold, the walls are treated with antiseptics. Plaster aligns the recesses, potholes, with a depth of up to five millimeters.

- Re-primer. This will provide adhesion, reduce material consumption - it will not be absorbed into the surface.

To hide cracks in the walls, it is recommended to use gypsum mixtures when puttying. Santegyps is more elastic when performing work, but its hardening takes much longer.

Tip: First you need to expand the crack a little, increase its thickness and depth.

You can increase the roughness by scratching the entire length of the crack with a knife or any sharp object. The gap is carefully treated with a primer, and then putty is performed.

How is putty applied to walls?

Where to start puttying? First of all, you need to properly prepare the putty solution.

Cooking Instructions:

- A little water is poured into the container.

- Putty is added.

- It is mixed with a simple spatula.

- To get a homogeneous mixture, an electric drill with a mixer is used, water is gradually added.

Tip: The readiness of the putty is determined by the consistency, so that it becomes elastic and adheres slightly to the spatula. When draining from the wall - putty is liquidish. A little dry mixture should be added to it to correct the situation. If there are lumps in the putty, it is too dry.In this case, water is added little by little, mixing thoroughly to obtain perfect uniformity.

Rules for puttying walls:

- Applied starting putty onto the wall with a large spatula. The material is taken in medium portions, after which it is evenly distributed over the entire surface. In this case, the tool must be placed at an angle of about 30 degrees. Putty is applied diagonally using one movement. To avoid protrusions and sharp transitions, all subsequent layers are overlapped.

Tip: When coating the starting layer, putty should be mixed with a small amount. In this case, the occurrence of dry particles that reduce the quality of work can be avoided. You should not be very worried about the appearance of ugly stripes from the spatula - they will hide perfectly with the finishing putty.

- It is recommended that flat corners be processed using a corner trowel. Work execution technology:

- a small spatula covers a small layer of material to the entire height of the existing corners or slopes;

- gently the surface is leveled with an angular spatula;

- the putty layer dries out within 24 hours.

- After the final drying of the leveling putty, a decorative layer is applied with a large and small tool. At the same time, a small amount of the mixture is superimposed on a large spatula with a small tool.

- Putty mixture is evenly applied to the surface, with a layer thickness of up to two millimeters.

How to putty the walls? Before you putty the wall for painting or wallpapering, you need to wait until each layer has completely dried. The start and finish putty, its first ball, must be dry. This will take approximately 12 hours. Then putty is putty.

After drying, final sanding is completed.

Tip: Before applying all subsequent coatings, the previous one should be primed.

How to: putty or putty on the walls? Both options can be used, each chooses what he likes best. All the details about puttying the walls are shown in the video in this article.

The most difficult thing is to properly putty putty so that it is not liquid, but not solid, and it is difficult to putty the corners - everything else is quite simple and even a novice can easily cope.

The most difficult thing to putty on is to prepare the mortar and putty the corners. The first is difficult, because the solution should be moderately liquid, and moderately solid. And the second, because non-professional angles are usually hard to give.