What surfaces can be putty and how to learn to putty?

Hard putty of the building bases - a preparatory stage of repair before finishing. The goal is to level the surface and repair the defects. Beginners who make repairs with their own hands should familiarize themselves with the rules for choosing and applying the composition.

The content of the article

What surfaces can be putty?

Putty is recommended to be applied on the following construction substrates:

- Stable. The surface should not peel off, otherwise the putty after some time after hardening will leave together with the finishing material, for example, with wallpaper.

- Porous. Putty does not hold well on smooth material - plastic and glass. The composition must penetrate the pores of the building base and fill in the defects, but there are mixtures that hold even on a smooth surface. For example, a product based on stone flour. This component provides adhesion of the material and the building foundation.

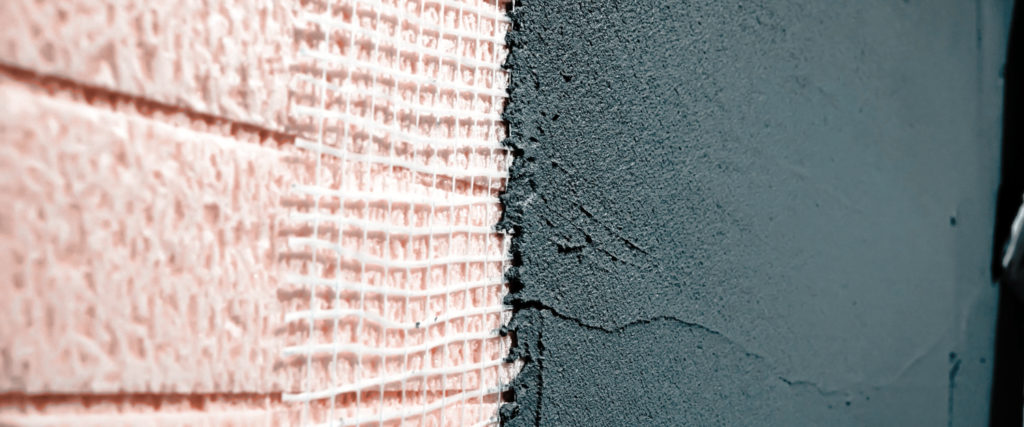

- Tough. Soft building substrates cannot be putty, but if the material is reinforced with a reinforcing mesh, then such surfaces can also be putty.

Putty surfaces

Concrete and cement

It is not difficult to choose a tool and putty concrete and cement, if the instructions are studied.

Types of putty

A concrete or cement base is recommended to be putty with a gypsum compound. The product is easy to apply, does not shrink, smoothes the surface and covers up mechanical damage to the material. Advantages - ease of use and reasonable price. The product is used only in a dry room, since it does not have moisture resistance.

If repairs are carried out in a humid room, it is recommended to use a cement mixture. The product is easy to apply, but shrinks.

For rooms with high humidity, a polymer product is also suitable. The product has good characteristics - it does not shrink, is easy to apply, provides waterproofing of the building base, smoothes it and closes damage. Of the shortcomings, only a high price is allocated.

Putty rules

If we say how to learn to putty a surface of concrete and cement, then for this you need to familiarize yourself with the rules of the work and apply knowledge in practice.

The first stage - dismantle the old coating, clean the walls, floor or ceiling from dust and degrease the surface. After the base has dried, apply a primer. Then, when the primer hardens, close the gaps, as the photo below. Next, put the first layer of plaster. Wait for the composition to dry and clean the material. Apply primer and topcoat. Next, grind and ground the surface. After that, go to the finish.

Fiberboard and other wood materials

Fiberboard (and other wood-based surfaces) is in itself a flat material, but it is also recommended to putty it to mask the joints and protect the material from mechanical damage.

Types of funds

When the question arises of how to putty on fiberboard and other wood-based surfaces, then professional craftsmen advise using materials that are suitable for wood:

- Acrylic composition. The tool can be used for all types of building base.The material is easy to apply, does not make the surface heavier and provides waterproofing.

- Latex remedy. The product is plastic, easily applied to the surface with a thin layer. The disadvantage is the high price.

- Two component product. The composition of the product includes epoxy resin, so the product is also called epoxy putty. The material is easy to apply, smoothes the foundation and conceals defects.

Putty rules

If we talk about how to putty fiberboard, then professionals recommend sticking to the following algorithm of work:

- prime the surface with an acrylic primer;

- fix the mounting grid;

- apply starter putty on fiberboard;

- after the composition dries, treat the surface with finishing putty;

- sand the surface and apply a primer.

Expanded polystyrene

This material, as well as extruded polystyrene foam, which is commonly called penoplex, is used for external and internal works. Products are made on the basis of foam by heat treatment. Materials belong to the category of soft surfaces, therefore it is recommended to putty them with a special composition and according to a special technology.

Types of composition

When the question arises of how to putty polystyrene foam, polystyrene foam and polystyrene, then professionals recommend looking at the composition. The products should not contain solvents or acetone, since these substances destroy the material. Masters advise using products that contain glue. Such a component improves adhesion of the material and putty.

Putty rules

It is important to know not only how to putty these materials, but also how to putty foam, polystyrene and polystyrene.

Work rules:

- seal joints and other cracks with glue-foam;

- treat the surface with a needle roller;

- apply the primer in two layers;

- fix the perforated corners on the slopes and outer corners;

- putty on the surface, starting from the slopes;

- fix the reinforcing mesh on the material and pass with a spatula;

- wait for the first layer of the composition to dry and apply the second layer of putty;

- primer the surface;

- wait for the primer to dry and apply the finishing putty;

- sand material with fine crumb P 150;

- clean the surface of dust and apply two layers of primer.

Polyurethane foam

Polyurethane foam - building material that is used indoors and outdoors. To putty it, you need to be able to choose the right tool and know the technology of work.

Types of putty

Unprofessional finishers often ask how to putty foam on the floor. It all depends on the place of work. Outside the premises, it is recommended to use cement or polymer putty. For internal work adhesives are suitable.

Putty rules

The mounting foam is putty as follows:

- take a clerical knife and cut the edges so that the surface becomes smooth;

- putty;

- wait for the composition to dry and clean the surface.

Foam block

How to putty foam blocks is a matter of unprofessional finishers. The answer is nothing. Putty is not applied to the foam block, since the composition will not adhere to the base or will become covered with cracks. Roughnesses of material are covered with plaster. After that, finishing is done.

Puttying the balcony

Puttying the balcony should be a composition for outdoor work. Cement and polymer compositions are suitable, but you also need to focus on the surface material of the loggia. For masonry, cement or concrete, these same tools are suitable. If the surface is made of foam and other similar materials, it is recommended to use an adhesive. Accordingly, the technology of applying putty also depends on the building base.For hard surfaces, a reinforcing mesh is not needed; for soft substrates, reinforcement is a must.

General principles for filling the balcony:

- prepare the surface: clean and degrease;

- prime the base with two primer layers;

- putty; if necessary, fix the reinforcing mesh;

- prime the surface and wait for the composition to dry;

- apply the finishing composition;

- take a break so that the product stiffens (the drying time is indicated on the package);

- sand the surface with sandpaper;

- prime the base and finish.

The video in this article demonstrates how to properly putty the balcony.

Puttying the pool

When the question arises as to how to putty the pool, then only moisture-proof compounds for outdoor work - cement mixes - are suitable for this work. Such material hardens when in contact with water. The algorithm of work does not differ from the puttying of the balcony with the exception of reinforcement. No mesh is used for the pool.

The choice of putty depends on the surface and place of work - unprofessional finishers should remember this when buying materials.

Tags: concrete