Stone furnaces for stoves and fireplaces: make a choice

Everything should be beautiful in the house, including the stove, if there is one in it. Now in general it is very fashionable to have in the house: if not a stove, then a fireplace.

But in order for it to look harmoniously in the interior, you need to choose a material for the facing that will not only decorate the fireplace, but also have a certain strength, resistance to heat. And one of the materials with the necessary properties is decorative stone.

In our article, we will talk about the types and properties of this material, and how to decorate fireplaces with stone: natural and artificial.

The content of the article

Stones and minerals

Necessary properties for furnish furnacespossesses most natural stones. Only the degree of their strength and heat resistance, the texture of each type, the presence of deposits, the methods of production are diverse - ultimately, their value depends on these factors.

Stone fireplace decoration should be carried out not only based on the financial capabilities of the customer, but also taking into account the specific properties of the material.

Rubble stone

The most common and affordable cost is rubble stone, which can have torn or tile forms. By the definition of “rubble stone” is meant pieces of limestone, dolomite or sandstone.

So:

- They get a boot by developing local rocks: both erupted and sedimentary. Crushed stone is processed into crushed stone, used in the construction of buildings, technical structures - this allows its strength coefficient.

- Decorative furnish of stoves with stone, most often made of rubble stone, and not only natural, but also artificial. This type of masonry is perhaps the most ancient.

After all, this is what is called a running stone that does not have special value. And any surface decorated with its help looks very good.

- Natural stone is quite heavy, certain costs will be required not only for its purchase, but also for delivery. And not every design can support its weight.

Making an imitation of rubble stone is a good alternative, given the fact that you can do it yourself and at home. - To do this, you need some stones for the sample, silicone, and the ingredients for mixing the solution: cement, sand, pigments. You can even buy ready-made dry mix, sold in bags of 25 kg.

It is enough to mix it with water, as prescribed by the manufacturer's instructions - and the solution is ready. - The main thing is that cement is the binder in the basis of the composition for such production. The decoration of the fireplace with artificial gypsum-based stone is not performed.

Gypsum does not have the necessary properties for this, and can crack when heated and cooled. - The manufacture of stone begins with the selection of capacity, which will serve as a formwork. It can be a plastic, metal or wooden box, in which you can put one large, or several small stones.

You can make several forms at once, if you need to make many copies. - Samples are lubricated with any lubricant, it is possible with lithol or solid oil, after which liquid silicone, which is sold in bottles and cans, is poured into the formwork. The silicone is tamped with an ordinary paint brush, and its surface is leveled with a spatula.

Tools should be moistened with soapy water, or any dishwashing detergent.

- It takes up to three weeks for the silicone to dry, after which the mold will be ready for use. About half of the mixture is poured into it to make a stone, and compacted by shaking and tapping.

- To give the stone additional strength, pieces of a reinforcing mesh are placed on top of the solution, after which the rest of the solution is poured. In the second layer, you can not add dye, so it will be more economical.

- When the form is completely filled, a relief is created on the surface of the solution, which is necessary for good adhesion to the surface of the furnace during lining. For this purpose, you can use any sharp object - a nail, a stick, a comb, or a spatula with teeth.

The finished stone is removed from the mold after 12 hours, but it will take another two weeks to gain strength.

This simple method is used not only for the manufacture of artificial stone, but also all kinds of stucco elements, baguettes, tiles and gypsum panels. If you are interested in this topic, and want the artificial stone for decorating the fireplace to be done by yourself, we recommend that you first watch the video.

Onyx

Often, stone decoration of fireplaces is carried out using more expensive, semiprecious breeds. This category includes a very beautiful natural stone called onyx.

Finishing any interior details with onyx is suitable for those who want a real exclusive:

- Many natural stones have not only wonderful aesthetic, but also healing properties. Therefore, they are so attractive to humans, including onyx.

- This stone has a beneficial effect on the vascular system, improves blood circulation, calms, improves performance. All over the world this is confirmed not only by doctors, but also by people in contact with this wonderful stone.

So sitting by the fireplace, lined with onyx, you will not only admire its beauty, but also feel an unusual surge of vigor.

Thanks to the translucent structure of onyx, fireplaces are made with internal lighting - an unusually effective design is obtained. In the thickness of the illuminated stone, all veins and inclusions are visible.

Onyx has a lot in common with marble in structure and appearance, therefore, stone fireplace decoration is often combined, as in the photo above.

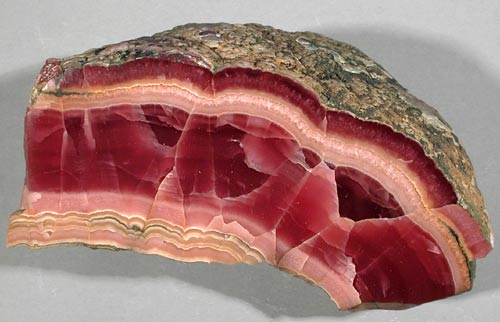

Rhodonite

This stone has several names: orlets, ruby spar, fauerlite. In the East, it is called the "stone of the morning dawn."

And all because this mineral was formed from the combination of magma with rocks rich in manganese. This explains its pink color, which can have a variety of shades: from raspberry to brown, in the mass of which there are bright blotches of ruby color.

For all its beauty, rhodonite also has a ton of other wonderful properties. It is very dense and hard, has a glass luster, is translucent.

And most importantly, rhodonite has a high heat capacity, which makes it possible to use it not only as a facing of fireplaces, but also for decoration of sauna stoves. And for this, not every stone is suitable, because the temperature in the bath stove is incomparably higher than in the fireplace.

Talc magnesite

Since we are talking about bath stoves, it should be said that volcanic rocks are best suited for their decoration, one of which is talc magnesite. This stone has the ability to accumulate heat, heats up quickly, and cools slowly.

Moreover, he has a good appearance. Decorating stoves with stone with such properties is just a gift for those who like to take a steam bath.

So:

- If talc magnesite is suitable for facing bath and metal stoves, then there is no need to talk about fireplaces. It not only has a beautiful texture, but also has a surface velvety to the touch.

Moreover, the stone does not glow to such an extent as to burn. You can safely touch its surface with your hands, warm your back. - Decorating the fireplace with a decorative stone of volcanic origin gives other advantages. The most important thing is to reduce fuel costs.

Giving more heat, such a stove will require a minimum amount of firewood. - Talcochlorite and talcocarbonate have the same properties. These are related stones, having only slight differences in composition and shades.

The heat emanating from such stones is very soft, relaxing, their heat waves are close in value to the wavelength emitted by a person. - Talc magnesite stones, due to their infrared radiation, help slow down the aging of the skin, the production of hormones and vitamins by the body. All this has a beneficial effect on the general health of those people who regularly come in contact with this stone.

There are so many breeds used for decorating stoves and fireplaces that it’s simply unrealistic to talk about everything within the same article. Everyone knows about granite and marble - there is not a single person who would not see how they look.

In each city there are monuments, memorials, sculptures made of these rocks. Therefore, it is not surprising that they are used for decorating fireplaces - it is both expensive and rich.

But there are other types of rocks that not everyone knows about. For example - a coil, which in our country is mined in the Urals.

It also has medicinal properties, and got its name due to a greenish spotty color resembling snake skin. This is jadeite, which was used in ancient China to create jewelry and sculptures along with jade.

So there is a choice, and considerable - and for each wallet there is a price.

Flexible stone

One cannot but mention the flexible stone, or, as it is also called, acrylic tile, which appeared relatively recently in the construction markets. This material has its own wonderful qualities.

Of course, it can not be compared with marble or rhodonite, but the decoration also looks good.

- Due to its flexibility, acrylic tiles can be used in the facing of semicircular interior elements, which is impossible to make with natural stone. And this can be not only a circular oven, but also columns, pilasters, parapets of balconies.

- The main property of this material is that it can withstand heat up to 600 degrees Celsius. That is why, today the decoration of fireplaces with flexible stone has gained such enormous popularity.

- This stone is made directly in places of extraction of sandstone, which serves as raw material for production. Experts look for beautiful textures on sections of the mineral, grind them and apply to the textile base with acrylic resin. Small particles of sandstone firmly adhere to the fabric, transferring the stone pattern to it.

Acrylic not only holds together the grains of sand, but also gives the resulting product strength and flexibility. Its texture is unique, as is each individual stone.

And given that only natural raw materials are used in production, flexible acrylic tiles can also be considered natural finishing materials.

Facing preparation

The first step in preparing the surface of the stove or fireplace for facing is to prepare its base surface:

- A reinforcing metal mesh with cup-shaped protrusions, which should be directed outward and upward, is mounted. Thanks to them, the decoration of the furnace with decorative stone is facilitated - the solution will not drain down.

- In order to qualitatively surround the corners of a fireplace or stove with a mesh, you need to take wooden bars, and nail them on the sides. In this case, sufficiently long roofing nails are used, which must be driven into the seams of the brickwork.

- The mesh should be fixed very securely, but a small gap should form between it and the masonry.Indeed, when heated, the brick expands, slightly increasing in volume, and too tight a “shirt” can crack.

The gap and protect the decorative surface of the fireplace from cracking.

- You need to start facing from the corners, gradually moving to the front side of the furnace. For the top row, stones of the same height are selected and arranged strictly horizontally. When fitting elements between them, you need to leave a small gap of about 1cm.

- The furnace hole must be framed by metal corners before facing work. After the corners of the furnace are already finished with stone, go to the left side of the furnace, and glue the stone around its perimeter.

Before applying the adhesive solution, the stone is moistened with a damp sponge or spray, and the place where it will be mounted is wetted. - The masonry mortar is carefully applied to the back of the stone, grooves are made with a notched trowel, and they are pressed against the surface of the furnace. The stone needs to be slightly moved to better disperse the solution.

It is necessary to ensure that it does not fall on the front surface of the stone, spots may form on it. - It remains only to wipe the seams between the stones. For this purpose, special heat-resistant grouts are sold.

In order not to stain the surface of the stone, it is better to use a special bag to apply the grout. It is filled with a solution that is squeezed out of the bag about the way confectioners do, decorating the cake with cream.

The applied grout is left for an hour to harden, and then its excess is removed, giving the seams the desired shape and depth. No tools are required for this, you can use a wooden stick, which is eaten by sushi.

Similarly, the fireplace is trimmed with a flexible stone. It will be possible to flood the fireplace no earlier than two days after finishing.