Furnishing furnaces: choose the material and do it right

Over time, the Russian stove was constantly modernized, in order to create the most optimal conditions for fuel combustion. An additional hearth appeared in its design, allowing to separate the heating and cooking functions.

Attention is also paid to the appearance of the stove - the village hut is practically a thing of the past. We will tell you how to finish a brick oven, and what heat-resistant materials for furnishing furnaces are better to use in a particular case.

The content of the article

Plastering the furnace

The easiest way to finish the oven is plastering. Naturally, now no one is coating the stove with his bare hands, as our ancestors did.

And the secrets of preparing a clay mixture do not need to know. There are heat-resistant dry mixes for plastering stoves and fireplaces on sale - diluted with water, as prescribed by the manufacturer's instructions, and the solution is ready.

So:

- You can start any cladding only a month after the end of the masonry work. It is necessary that the solution is completely dry, and the structure shrinks.

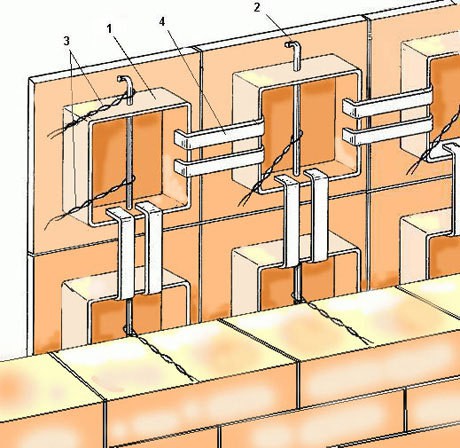

Finishing a brick stove with stucco requires some preparation. - To do this, it is necessary to clean the surface of the brick from the adhering mortar, and select it from the seams by about a centimeter, and then treat the masonry with a penetrating primer. Then the furnace body is fitted with a metal mesh with a small mesh, no more than two centimeters in size.

- It is fixed with long nails, driving them into the seams between the bricks. The grid should not fit the stove too tightly, but reliably enough.

After all, the brick expands when heated, and if you do not leave a small gap, the plaster layer will crack. To better understand how this is done, watch the video. - The grid will make the surface of the brick rough, which will allow the mortar to hold well. When the frame is finished, the furnace must be heated and then its walls moistened well - the solution is applied to a warm, damp surface.

- The first batch of the solution is made more liquid, and applied in a thin layer. The surface is leveled, shaped into corners, and, after rubbing the plaster, left to dry. In the process, the furnace is no longer needed.

When dried, the first layer will certainly crack. This is normal, the cracks will need to be slightly expanded and moistened with water.

Next, you need to apply a second layer of solution. It happens that it is necessary to perform plastering three to four times.

But then it turns out a very strong and durable coating.

Stucco Furnish Finish

After waiting for the plaster to dry completely, you can proceed to the finish. It may not just be whitewashing.

The surface of the furnace can be given any color, hand-painted, use dot decorative elements, as in the photo.

So:

- For whitewashing use chalk or lime, with the addition of blue and salt. Salt strengthens the composition, and prevents whitewashing.

By the way, the salt also has the same effect on the plaster mortar - stoves often add it to their recipes. - Of course, there are many heat-resistant paints that you can use. But their price is not comparable with the cost of chalk.

But, the interior decoration furnaces can be made individual, colorful. In addition, all heat-resistant paints are not afraid of water, so the surface can be washed.

And its service life is practically unlimited. - There are many types of such paints: alkyd, silicon-organic, organo-silicate. Each of them has its own advantages and colors, which will acquaint you with the purchase. Furnace in the kitchen can be made with refractory liquid glass.

It can be painted with ordinary gouache and get an original and unusual decor.

- There is also such a type of plaster from which three-dimensional elements are made using curly matrices, imitating the texture of all kinds of materials: wood, brick, stone, etc. The basis of this plaster is cement and mineral fillers. In our example, decorative plaster imitates masonry.

- You can do it this way: apply a regular, still raw layer of plaster, to geometric patterns called rustics. For their application, they use a binder, or even an ordinary ruler, and then they paint it - it turns out original.

On a leveled surface, furnaces can also be finished with cullet. This type of wallpaper is a fire-resistant finishing material, which in case of fire does not emit toxic substances.

And all because fiberglass is made from non-combustible raw materials: glass, dolomite, quartz sand and soda. Fiberglass wallpapers are incredibly durable and can be painted up to a dozen times.

To the question: "How to finish the coarse stove?" - the answer is simple. The cob is faced in the same way as the oven itself.

And if it is fiberglass wallpaper, then they can be pasted over the entire room.

Tiling the stove

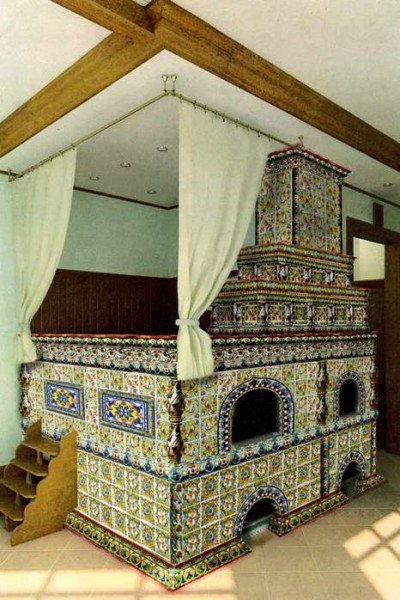

This is the most expensive and oldest type of decorating stoves. Tile decoration of the stove or fireplace is done by mounting on their surface a ceramic product of a rather complex shape.

So:

- On the front surface, the tile looks like a glazed ceramic tile, and on the reverse side it has a rump - a special ledge that allows you to mount tiles in brickwork. Their fixation is carried out by the anchor method, for this there is a special furnace wire.

- Tiles can be of any color, have a relief, any drawing, portrait, or image of animals. These products are almost unique, and can cost more than the stove itself.

- Ancient tiles have always been a luxury item and had artistic value. They are now made, burned and painted only by hand - hence the high cost of products.

- Manual production does not allow you to get products absolutely identical in shape and color. Therefore, the decoration of the stove with tiles begins with their sorting.

The selected parts are ground and adjusted to each other. Previously, this was also done in a manual way, now this work is somewhat mechanized. - There are several ways to install tiles, but it is more convenient to produce such a cladding simultaneously with the erection of brickwork. Doing it yourself is unlikely to succeed; a specialist should work here.

Such a masonry is a monolithic structure, repeatedly reinforced, the service life of which will be almost unlimited. That is why in some old buildings, almost destroyed, often only a tiled stove remained intact.

Tiled finish

Very few people could afford the tiled cladding, so they thought how to finish the stove in the house so that it was just as beautiful, but cheaper.

Ceramic tile was such an alternative:

- In the lining of furnaces, tiles began to be used for a long time, and the most similar to tiles can be called majolica. This is a glazed ceramic tile produced by double firing.

It is also called glazed terracotta. - Majolica is made of colored clay, with a bright pattern under a layer of glaze. It is unusually porous, has a rounded shape, and is designed for furnaces and fireplaces.For wet rooms, majolica is not used.

- A cheaper option for facing stoves is terracotta non-glazed tiles. It is no less durable than majolica, has a more dense structure, which allows it to be used for exterior decoration of facades.

- This is facilitated by the various texture of the tile, imitating at least a brick, even a stone. Decorating a stove for a wooden house with terracotta tiles would be a great option.

For such a room, you can always choose the appropriate texture and color.

- The most durable option of all types of ceramic tiles can be called clinker. This is facilitated by the use of highly plastic clay grades used for its manufacture, and the special technology of firing in a hermetically sealed furnace.

- Clinker tiles can also be glazed, but for hot surfaces it is better to choose non-glazed options - they have a denser structure, and their expansion coefficient is lower.

- For facing of furnaces not only tiles, but also clinker bricks can be used. Finishing the furnace in the bath with refractory bricks is the simplest and most affordable for independent work.

In this case, another layer of brickwork is performed along the contour of the furnace - facing. - As for the tile, it would be wrong to think that it is simply laid on a solution or glue, as in a bathroom. Before finishing the brick kiln with tiles, it is necessary to perform plastering with reinforcement, as we described at the beginning of the article.

- For greater reliability, it is better to fix the second layer of the mesh, which will give additional strength to the tile adhesive. By the way, about glue: for facing stoves and fireplaces special heat-resistant compounds are sold, which are diluted with water to the desired consistency, as well as plaster.

The smaller the tile in size, the stronger it will hold on to the base. After grouting the joints, the lined surface can be coated with heat-resistant silicone impregnation, which will protect it from contamination.

This applies to porous types of tiles and natural stone. Tiles can be used to decorate not only the Russian stove, but also modern metal stoves and barbecue, which are installed in the kitchens, summer houses or courtyards.

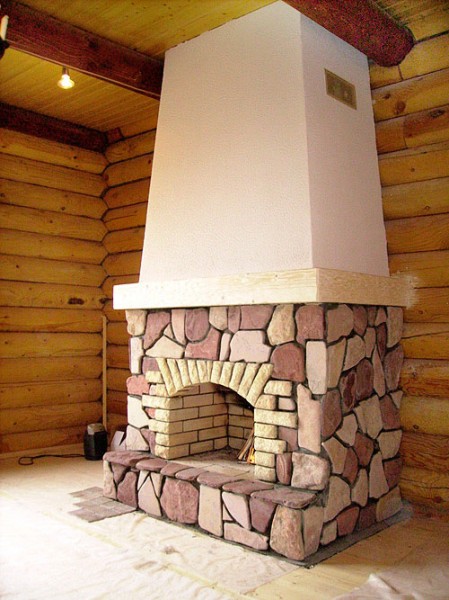

Stone finish

At its core, this finish is not particularly different from tiled cladding. The difference is only in the preparation for installation, and very big.

- After all, the stone does not have a standard and regular geometric shape, so its adjustment takes a lot of time. Especially if you use a wild stone.

Masters lay it on the floor in the order in which it will be mounted on the wall and mark each element. - A natural stone can be used to decorate a stove in a sauna, and one can also not think about how to finish a wood stove in a bath. The heating temperature of such stoves is much higher than that of a Russian stove, so a stone for them is the best option.

- Sauna stoves operate in extreme conditions, not only because they constantly overheat, but also come in contact with water. Finishing the furnace in a steam room requires first encircling its body with a bandage from a metal corner.

Not every stone is suitable for bath stoves, but there is a breed that seems to be specially created by nature for this purpose. This stone is called talchochlorite.

It belongs to mountain volcanic rocks and has the highest heat capacity, three times higher than that of stove bricks. Having drowned a stove-stove, lined with talc-chlorite for a couple of hours, the heat is enough for a whole day.

There is a saving not only in fuel, but also in time, since this stone heats four times faster than brick.You can add to its advantages a beautiful texture, which even the most powerful heating cannot destroy.

After all, this rock was formed from lava, the temperature of which cannot be compared with that created in the steam room.