Cladding with wood panels - warmth and comfort in your home

At first glance, when evaluating the interior, the wall decoration takes over. She sets the mood, is the backdrop for furniture, accessories and other design components.

When the walls are lined with wooden panels, the room is literally filled with a feeling of warmth and comfort, solidity and sophistication. If you want to achieve just such an effect, then this is your material.

The content of the article

Types of wood panels

There are many types of such panels, but all of them can be conditionally divided into two large groups. The first includes natural wood made from solid wood, the second - from compressed wood processing waste.

Natural wood panels

Wood panels for wall cladding and ceilings are made from such valuable varieties of wood as oak, alder, cedar, cherry, maple, mahogany, etc. They finish hallways, cabinets, living rooms, and if the panel is covered with a special water-repellent wax on all sides, then it can also be used for facing rooms with high humidity.

Note. In such cases, installation is necessarily carried out with a ventilation gap between the cladding and the wall.

This finish may look very different depending on the panel design. Smooth, with a seamless connection, are great for a modern style, and paneled or carved will help create a solid classic interior or design a room in Provence style.

A big drawback of panels made of valuable varieties of wood is the high price. To reduce it, manufacturers launched the production of multilayer panels.

The inner layers are made of inexpensive species - spruce or pine, and the upper decorative of oak, beech, walnut and other valuable wood. Moreover, all three layers are glued together so that the direction of the fibers in each of them is mutually perpendicular.

This eliminates the linear deformation of the panels due to humidity and temperature. In this regard, they are more reliable than solid panel.

Like any other wood products, wall and ceiling panels need protection from moisture, insects, and dirt, so they are coated with a special wax with colored pigments or acrylic varnish.

For reference. Species such as cedar or red pine look great without coating and do not require a protective layer.

The main advantages that are possessed facing panels made of wood, this is naturalness and environmental cleanliness, unique appearance, excellent thermal insulation and acoustic properties.

Wood based panels

In addition to the array, sawdust and shavings are used for the manufacture of cladding panels in a special way glued together and formed. As a rule, to bind the fibers and give the material strength, binding agents are introduced into the wood pulp, after which it is pressed under high pressure and high temperature.

In this way, MDF and particleboard have long been known to us, as well as MDF panels that have recently appeared on the market. All of them differ from each other in varying degrees of harmful resin content and operational characteristics.

So:

- Particleboard (wood chipboard) is produced by extrusion pressing of sawdust and shavings.Formaldehyde resins act as a binder, the content of which the area of application of the panels depends on.

Safe, suitable for finishing residential premises are considered stoves, the content of free formaldehyde in which is not higher than 10 mg per 100 g of weight. Particleboard is not used for finishing wet and unheated rooms (loggias, balconies, terraces, etc.), since it does not have good water resistance.

- Fiberboard (wood-fiber boards) is made by hot pressing from wood fibers. From wood chipboards, they are more durable, environmentally friendly, resistant to moisture. However, the instruction does not allow mounting in places where there is a possibility of direct exposure to moisture.

- MDF (middle density fibreboard or finely divided fraction) is an advanced analogue of medium density fiberboard. A connecting element in such panels is the natural substance lignin, which is part of natural wood.

That is, the material does not contain harmful synthetic resins, so they are completely safe and environmentally friendly. MDF is characterized by high water resistance and mechanical strength.

All the materials described are available in the form of panels of various shapes, thicknesses, and have a diverse decorative surface. It can be square or rectangular plates or long panels such as lining.

Their front surface is most often covered with a layer of laminated paper with any pattern or veneer of valuable varieties of wood.

Thanks to such a coating, wood-based lining panels acquire not only an aesthetic appearance and absolute resemblance to solid wood products, but also protection against pollution, moisture and ultraviolet rays. They can be wet-cleaned without risking warping or swelling. Of course, abundant wetting, the use of solvents and abrasive products should be avoided.

For reference. In addition to wood, laminated panels can imitate other materials - brick or masonry, marble, tile, as well as be colored or with any pattern, ornament. More expensive models are finished with textiles, eco-leather, high-quality vinyl wallpaper on a special glue, spraying of mineral particles.

The advantages of panels made of wood materials include good sound absorption, thermal insulation properties, the ability to maintain a stable color and shape and not crack, as is the case with natural wood, ease of installation with your own hands.

Mounting Methods

Wooden cladding panels differ not only in structure, texture or color, but also in size, shape, profile. It is the configuration of the profile that determines the method of their installation.

In any case, the cladding is attached to a pre-mounted frame, which levels the surface and creates an air gap between the wall and the panels. When finishing external walls between the guides of the frame, you can fix the insulation.

So:

- Through installation involves fastening the panels to the crate with self-tapping screws with a recessed head. Subsequently, these holes are sealed with putty in the tone of the cladding and polished;

- The fastening of wooden panel panels is also done through, but the fastening places are subsequently hidden by skirting boards, overlays and cornices.

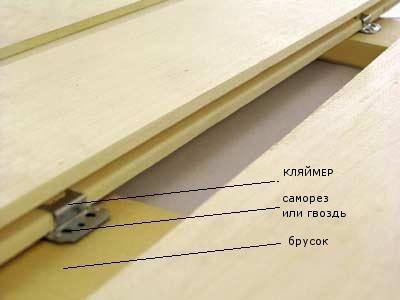

- If facing wood panel on the one hand has a groove, and on the other a comb (like a lining), it is mounted using special clamps, which are fixed with small studs or self-tapping screws. The next panel is inserted all the way with a comb into the groove of the previous one;

- There are panels only with connecting grooves at all ends.In addition to kleimers, docking strips or rails are required for their installation.

Such inserts may be hidden when their width is equal to the double depth of the groove. In this case, the panels are installed end to end to each other.

If the docking strip is wide and made in the form of a decorative rail, then gaps remain between the panels.

- Mounting on aluminum profiles. They can have a matte or anodized surface or be covered with a laminated film in the color of wood.

Installation and masking of joints and joints is greatly facilitated by the availability of accessories such as skirting boards, cornices, corners and other decorative elements. If you doubt that you can independently clad the ceiling or walls with wood panels, watch the video suggested in this article to better understand the technology.

Conclusion

No one will argue that wall cladding with wooden panels has not lost its relevance even with the advent of modern materials requiring minimal maintenance. On the contrary, natural materials are valued higher and higher each year for their environmental friendliness, unique natural look and warmth.