How to cut openings in load-bearing walls

Cutting openings in the bearing wall is quite a responsible matter. Indeed, it has a heavy load and it is necessary not to weaken the structure. To do this, amplification is done.

Today we will tell you how to cut an opening in a load-bearing wall while maintaining the load-bearing properties of the structure. You can find additional material on the video in this article and photo.

The content of the article

Wall Cutting Options

It will be possible to cut through the opening in the bearing wall in several versions. Today we will not talk about how to chisel walls with a chisel, but consider two options that are most optimal for this work.

Diamond cutting

You can make openings in the walls of the supporting plan using the above cutting without any problems and unnecessary noise. Diamond cutting of openings in load-bearing walls is most often found in this work. These settings do not form a vibration effect in such elements.

In the modern construction market, equipment for this type of work is presented in a wide assortment:

- For concrete floors, special aggregates are used for cutting joints of small dimensionswhose mass is not more than one hundred kilograms.

- If you decide to autopsy concrete, which has a large level of its thickness, then our equipment has a weight of about four hundred kilograms.

- Even as a working unit, you can use special equipment for cutting wallswhich attaches directly to the floor

Attention: To make an opening in the wall of concrete, the layer level of which is more than fifteen centimeters, you can use the cutting device, which is made in the form of a disk with a diamond coating.

Laser Technology

A more convenient technique for such types of work is laser cutting. More recently, this equipment was very bulky and stationary. At the moment, the construction market offers the latest cutting equipment with functions that greatly facilitate the process itself.

Laser cutting of concrete walls takes place thanks to gas discharge lasers. These units are used with great pleasure during dismantling, in saving people, as well as in emergency situations. Such a technique is especially needed where it is necessary to perform cutting in the walls of the supporting plan and where it is impossible to get close to them.

If you need to make a cutting aperture, builders take into account a number of important circumstances:

- Dimensions of floors

- The presence in the design of reinforcement

- Concrete wall manufacturer

- Building floor

- Is there an additional connection to the electric power network

- If near the construction site the opportunity to draw water for work.

How to make an opening in the wall of concrete

To carry out the cutting of the opening, first of all, you need to take permission from the competent authorities:

- Once you have been given permission, you can begin construction work. An easy way from the existing ones is to simply make a hole in the wall using a conventional sledgehammer.

- More intelligent methods include the use of a perforator in construction work, as well as tools for cracking a concrete surface. However, there is a danger of making cracks in the wall. Diamond cutting can be used for such purposes.It is practically silent and will not disturb your neighbors once again, vibrations will not form, short construction periods will be observed.

- Using a special unit / machine, we make cuts that we attach directly to our coating. We cut from two different edges.

Creating an aperture using diamond cutting is performed with extreme precision. After performing these manipulations, there is no more need to do the processing after cutting.

- Such cutting of concrete walls has a number of undoubted advantages due to the high speed of the cutting unit and a special technique without the use of impacts. This method is very safe, since during its implementation, the emission of tiny particles is not noticeable.

- The technique of such a plan has a high-precision mechanism, which makes it possible to comply with all the characteristics and create a bias. With this method, the wall will open along a marked line and without changing the degrees in the corners. Also, in these works there is no probability of cracks in the wall. This method is used to create openings in residential buildings.

Another interesting way to make an opening in the supporting wall is waterjet cutting.

- This method involves cutting a wall of concrete with a strong jet of liquid, which includes an abrasive. A plus of such work is the fact that concrete can be removed in the future, while the wall itself will not suffer. If we begin to increase the level of pressure, then the technique can literally flush the wall directly.

- You can create an opening in the bearing wall without using vibration or sound effect. However, this method can be described as a high probability of causing a fire. This situation may be possible due to the water in the composition. With this method of cutting, the thickness of the cut can be only about one millimeter. The technique is very simple in its installation and operation.

Sometimes you can use the oxygen cutting method:

- This type of work is characterized by the fact that oxygen flows into the iron tube under a high level of pressure. Ignite the tube from one end and make an opening in the wall with this part. For such purposes, it is pressed against the wall and holes are made in it.

- Using this method, you need to carefully look at the concrete coating. This method takes a lot of time and by its nature can be a lot of trouble. Particles of high heat and temperature begin to fly throughout the room, hence it is recommended to use protective equipment (for example, a mask to protect the eyes).

The first step is to conduct a series of preparatory measures in the room where the construction is supposed. First, we remove all things, and what remains is usually simply covered with a film to prevent dust and other particles from getting into them during operation.

- Next, we mark up our proposed opening. After all the above steps, we begin the cutting process. The wall itself is cut into small parts, which are then folded into a special sealant placed on the floor covering and protecting it from damage and deformation.

- It is possible to make an opening in the wall of concrete subject to some important recommendations. On a wall where the level of thickness is small, you need to spray a small amount of water so that it is possible to remove dust. A concrete wall, where the thickness is very high (from thirty centimeters), in turn, needs to be very moistened.

As soon as our doorway is ready, it needs to be fixed in a special way.

This type of reinforcement using metal structures is done using different methods:

- The channel is used in the work

- In special cases, fixing can also be done with metal corners.

- There are also other methods and the use of certain materials in construction

Making an opening in a brick

It is necessary to create an opening in brickwork with a great deal of caution in order to prevent accidental destruction and unnecessary damage.

Valuable advice: before increasing the opening for a door in a brick wall, it is imperative to strengthen the surface above it:

- For such types of work, you need to choose the row of bricks, which in terms of width is greater than the intended opening itself. There we will install a jumper. Next, we make marking work from two edges. We do wall cutting from all parts and then very carefully remove the cut surface.

- It is possible to make an opening in the wall of brickwork in several stages, first of all by dividing our surface into sections.

- In the same ways we create openings in other places, for example, where the window is located.

When creating an opening in such surfaces, you can get a small problem in the masonry itself, so we can fix the destruction of the bricks themselves. In order to prevent such defects, we need to take parkers (these are special tubes). We install them in the brick itself, and pour cement into the voids of the pipes.

Carrier Plan Constructions

If you want to make a cut along the load-bearing wall, you must necessarily obtain the appropriate permission from the authorities. The process of work and cutting in no way differs from the work described above. The only difference is the different ways to enhance the opening itself.

So:

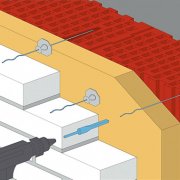

- For this type of installation, we create recesses from both parts of the surface of the future opening. In these parts we install a channel. We will be required to create such combinations four times. As a result, they form a common system. Their contraction is due to special studs.

- The cutting of the concrete wall under the arch itself is done without the use of optional reinforcements, since the whole system will be very durable thanks to specially distributed loads.

- To strengthen our opening, you need to perform the following steps: take a hammer drill and cut out the strobes in our wall surface.

Strobes should not be cross-cutting. They serve in the future for the installation of reinforcing structures. To cut the opening, builders usually use a channel.

The dimensions of the strobes themselves will be made dependent on the channel used. The first step is to correctly do all the marking work.

- In the created strobes we install channels, fastened with the use of special studs. On the side, the structure is joined using welding.

To make an opening in the wall when using the channel, use the following methods:

- We cut the channel according to the dimensions we need. The channels are taken in pairs.

- We connect such pairs and make holes in them. The distance between them should be about thirty-five centimeters.

- Next, we create niches for the studs. The channel is installed in the manufactured gate and through the holes we drill recesses in it.

- After installing the channels in the manufactured niches, we pass the studs from all ends with the washer.

- We connect channels

- Such a structural system perfectly spreads the load level on the surface.

The whole process of work ends after strengthening with metal amplifiers.

- As soon as our doorway is safely created, we connect the channel plates. They should have a thickness level of about four millimeters, and their width should be half a centimeter.

- Next, we put the plaster from the inside of the opening, for such a construction we use a grid of metal structures, it is superimposed on top of the channel itself. We must fill all of our niches that are obtained in the course of work with a hammer drill. We pay special attention to connections.

- If you want to create an aperture in an ordinary apartment, first of all, before its construction you will receive a permit from various authorities.If you proceed with such an installation without approval, the consequences can be terrible.

- To make an opening you need to spend a lot of time and have some experience in this field.

Finishing work

The final work is as follows:

- We connect the channel bars with two parts of the wall. We monitor the size of the used plate

- At the same time, we must add a channel in those parts where it was more difficult to get before.

- We put the plaster on the inside of the opening, apply a mesh of metal.

Attention: All work on creating an opening in the MKD should be carried out according to a strictly approved project. The life and health of people can depend on the quality of work!

Cutting the opening in the bearing wall is quite a responsible job. Here, never rush and do everything deliberately. The most basic thing is to make reinforcement of the structure. The instruction will help you avoid mistakes and do everything right. After all, the final price is quite high.