Finishing a wooden staircase: types of structures

As a rule, in buildings from 2 or more floors, a staircase is required. It can be made of metal, concrete or wood.

If finishing work on a metal or concrete staircase can be quite complicated, then finishing wooden stairs is not difficult.

The content of the article

The advantages of wood for the manufacture of stairs

As a rule, in most cases, wooden stairs are made of oak. The wood is strong and durable. The most important thing is its quality training.

Distinctive features:

- This material is initially dried and only then various antiseptic agents are applied to it.

- They help not only protect the material from harmful insects, but also give it strength and reliability.

- After proper processing, the wood will not absorb moisture so intensively, and will be exposed to weather and climatic conditions.

- It is also worth considering that a wooden staircase without finishing work with the use of varnish or any other material may eventually begin to deform and lose its original appearance.

Types of Wooden Stairs

The design of wooden stairs can be of different formats:

- Screw.

- Multimarch.

- Direct.

The photo shows examples of such stairs that are striking in their originality.

The staircase consists of:

- Bowstrings.

- Platforms (straight and marching stairs).

- Steps.

- Railing

What you need to provide:

- In the process of building a staircase, it is necessary to take into account its convenience, first of all.

- The design should not be dangerous, with a convenient descent and railing.

- This aspect is especially important if there are small children in the house.

- The most convenient is the design, which has a width of at least 80 cm.

- The height of the steps is considered optimal 20-25 cm.

- As for the width of the steps, then everything will depend on the size of the stairs themselves and on its angle of inclination.

Tip. The most convenient and practical width of the step is considered to be a size of 20 cm. The leg becomes free on it.

It is also worth considering that all steps of the wooden staircase have protrusions. Such a protrusion should not exceed 2 cm.

Otherwise, lifting injuries cannot be avoided.

Spiral wooden stairs:

- The designs of such stairs are striking in their originality. They are very elegant and fit seamlessly into any room interior.

Their main advantage will be that they do not take up much space in space and can be placed anywhere. - Spiral staircases are made with fastening on one pole or with a small number of supports that completely do not spoil the appearance of the structure.

- The steps of the stairs are triangles with one right angle. They are attached to the string using self-tapping screws or an adhesive solution.

Tip. The manufacture of a spiral wooden staircase is best entrusted to professionals, since it will not work on its own to make all its details.

The price for this type of wooden stairs is quite high. All this is due to the complexity of the work.

Wooden multi-flight stairs

The constructions of this type of stairs are quite massive compared to spiral.

They may be:

- One-flight.

- Two-flight.

- Three flights and so on.

Design Features:

- In order to make more marches on the stairs, it is necessary to strengthen the structure and add additional supports to it. As a rule, two flights can be enough to climb to the second floor, but it all depends on the design of the room.

- What are such stairs? This is a set of steps on a bowstring that can be interrupted by small transitional areas.

Usually, such platforms serve as rotary. - Such structures are mainly mounted in the corners of the room, as they take up a lot of space. It is for this reason that each element of the staircase has rectilinear shapes.

Tip. This type of staircase should not be used in a small room, as it can pretty much hide the space.

Straight wooden stairs

There is no simpler wooden structure than a straight staircase. It does not represent a difficulty in manufacturing.

It also occupies a lot of space, and it is the poet who is best placed in the less functional area. For example, in a corner, near a wall, and so on.

Straight wooden stairs are more practical and convenient than previous views. Again, everything will depend on the level of the stairs.

Tip. This type of stairs in a very small room is not recommended, as you can increase the slope of the structure and it just becomes uncomfortable when climbing.

Railing of a wooden staircase

In process stairs finishes production of handrails is included.

They can currently be:

- Metal.

- Wooden.

- Glass.

Metal railing

Metal railings look very chic with wood. Differ in durability and durability.

As their processing, ordinary paint or a polymer coating is used.

Why are such designs good:

- They can be combined with decorative forged elements.

- They are a metal railing, two parallel-running pipes of a bowstring or one and perpendicularly mounted racks, on which decor elements are attached.

- Such railings are mounted on wooden steps using metal plates.

Wooden railing

Wooden railing on a wooden staircase creates the integrity and quality factor of the structure:

- They can be of various shapes.

- Very often a thread is used on them, which gives them uniqueness and originality.

- Handrails made of wood are strong and durable. Masters make various forms of such designs.

Tip. In order for such a railing to be able to serve for quite some time, it is necessary to make their high-quality finish using varnish means.

Glass railing

In order to use glass in the design of a wooden staircase, it is necessary to apply another durable material, on which glass will be mounted.

Design Features:

- As a rule, these are wooden or metal racks in which special fasteners are mounted.

- The glass thickness for the railing should be at least 3-5 mm. You can use imitation glass - transparent plastic.

This type of railing does not require special care. They can be cleaned with a special tool for a glazed surface and clean rags.

Tip. If wooden and metal railings can be used in any type of staircase structure, then glass railings are best used in a straight or marching staircase.

Finishing a wooden staircase

In order for the staircase in the house to serve for a long time, it is necessary to qualitatively make its finish. Here we are talking not only about proper care, but also about the process of finishing steps, railings, bowstrings.

Finishing wooden stairs can be done using:

- Paints and varnishes.

- Laminate flooring.

Paints for finishing wooden stairs

Decorating stairs with such tools is quite popular.With the help of modern varnishes and paints, you can create an original design.

You can use for this:

- Oil paints.

- Transparent varnishes.

- Opaque.

- Special tools to give a shade to a tree and so on.

To apply varnish you will need:

- Two brushes of different sizes.

- Sandpaper with large cells.

- Varnish or paint.

Stages of work:

- Previously, the surface must be qualitatively prepared. To do this, use sandpaper, which is processed. After that, the surface is cleaned with a conventional vacuum cleaner.

Tip. In this case, do not use wet cleaning of the staircase structure. The unprotected surface of the wood absorbs moisture quite easily and it will take time to dry. In addition, the shape of the wood may be deformed.

- Apply varnish or paint with a brush. To paint the stairs you need to start from above, gradually going down.

The number of layers depends on the desired result. As a rule, varnish is applied in 3-4 layers, and two will be enough paint. - If you want to give a shade to a wooden structure, then you need to use special tools. They are initially applied to the surface of the tree and it is necessary to give them time to soak.

After that, layers of varnish are already applied to them.

Laminate in wooden staircase

Wooden stairs with laminate trim look elegant, the same material can be done and concrete staircase. This material has excellent technical characteristics and properties.

There is a large selection of laminate flooring, which has different sizes and colors. Such material can be performed only on the stairs.

In order to carry out the installation of the laminate it is necessary:

- Special bedding material.

- Jigsaw.

- Metal corners to mask the edges of the material on the steps.

- Self-tapping screws.

- Screwdriver.

As a rule, there is an instruction on the packaging of the laminate, according to which the material is laid. Since the surface of the steps will already be flat, there is no need to level it.

Also, it will not be necessary to cover them with varnish or paint, as they will be protected by a laminate.

Installation of this material is quite simple:

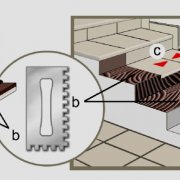

- For this, in each element of such a floor covering there are grooves that serve as fasteners for connecting each strip of the laminate.

- To strengthen the strength, all joints can be treated with adhesive or sealant.

- To adjust the required size you need to use a jigsaw, which will save time and effort.

- After the laminate is already laid on the surface of the steps, then the process of finishing the stairs proceeds to the installation of metal corners.

This is done using self-tapping screws and a screwdriver. You can watch a video showing the process of installing a laminate on a flight of stairs.

There is nothing complicated in such actions.