What does the class of linoleum mean?

Linoleum as an inexpensive and reliable flooring is in stable demand among Russians. Finishing household premises using linoleum for many years is a classic option for many families. Even for bathrooms, manufacturers came up with liquid linoleum, which successfully competes with tiles. But when choosing a coating, the buyer learns that there are a lot of types on the shelves of building stores, and the classification of linoleum is not one, they are classified according to all the main parameters: wear resistance, abrasion, fire hazard, coating thickness and scope.

What class of linoleum is best suited for different rooms in the apartment, we will understand in this article. Consider the difference between the classes of linoleum recommended for children and bedrooms, in which room the fire hazard class of linoleum is of paramount importance, in which rooms it makes sense to pay for higher classes of linoleum coverage, and which ones are more reasonable to save.

The content of the article

What does wear resistance mean?

It is difficult to say whether the classes of linoleum have differences, without considering which you can buy a really high-quality coating. Choosing a coating without studying the classifications of the material entails the risk of overpaying for linoleum (if it is too high a class for a given room) or moving the next repair closer (if the coating class is too low and will not withstand the loads). And even put the family at risk if linoleum seems toxic or unstable to fire.

In any case, if you don’t want to know all the characteristics of the selected linoleum, wear resistance is one of the main properties that we recommend to take an interest to before buying. The concept of wear resistance consists of abrasion and thickness of the material. Moreover, these components are mutually compensated: the wear resistance of the material will remain the same if its thickness is reduced, but its abrasion is increased, and vice versa, and the thickest coating of the lowest abrasion will be the most wear-resistant.

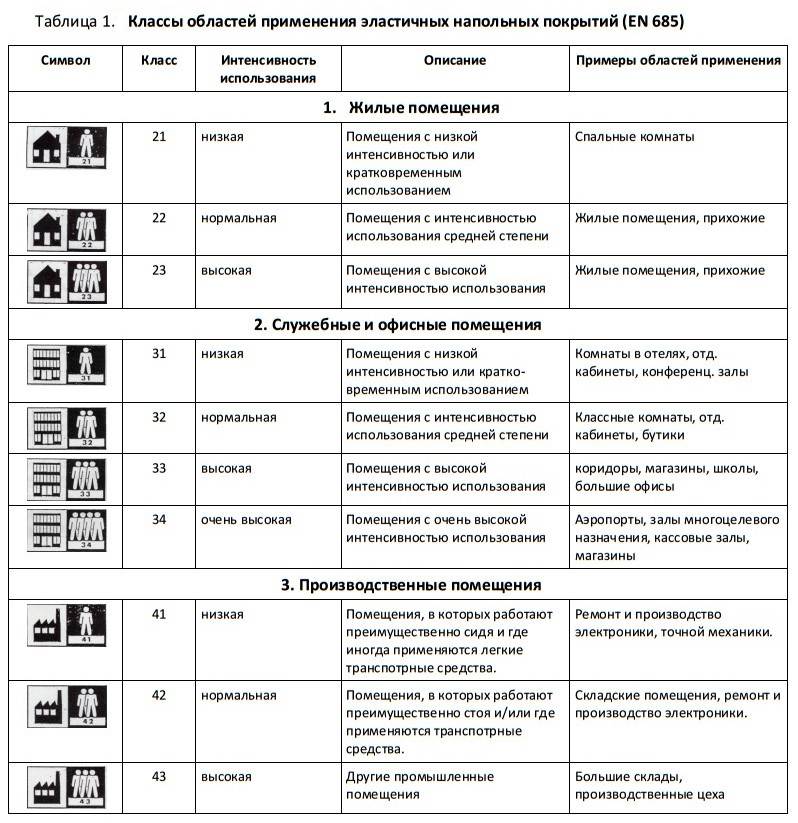

Since 1995, in our country, the class of linoleum wear resistance is determined according to the classification EN 685 developed in the European Union. It also regulates the conditions in which it is recommended to operate the material. According to this standard, each coverage model receives a two-digit number. The first figure indicates the type of room for which the properties of this linoleum are sufficient. For residential premises - 2 (household). For office - 3 (semi-commercial and commercial), for production - 4 (special). The second digit (from 1 to 4) indicates the intensity of the load that the coating will withstand without damage.

Given these designations, it becomes clear that the class of linoleum 32 means material for the office, designed for average load, and 24 - flooring for domestic premises, which can withstand the highest load. In the following sections we give a detailed description of each class of linoleum.

Degrees of abrasion

But there are class designations of linoleum not only in numbers, but also in letters. For example, the manufacturer or seller in the description says that he is selling class M linoleum. Thus, the degree of abrasion of the coating according to EN660-1 is characterized. Compliance with its standards is checked by a special test.Using measuring equipment of high accuracy, the reaction of the sample to rolling by a rapidly rotating abrasive roller is recorded. The coating is subjected to this test under the conditions specified in the standard. Linoleum groups are also wear-resistant. 4. The letter “T” marks a coating of high wear resistance, which loses during the tests no more than 0.08 mm of the thickness of the working layer. This group is the most durable and the most expensive. Linoleum, marked with the letter “P”, is also solid and strong; the thickness changes during the test by only 0.15 mm. If the material is abraded to a thickness of up to 0.3 mm, the letter “M” is assigned. Democratically priced coatings with a loss of thickness of up to 0.6 mm are marked with the letter “F”.

But focusing only on the price is wrong. As mentioned above, wear resistance depends on both abrasion and thickness. Therefore, the thick material assigned to group M is identical in wear resistance to the thin linoleum from group T.

Class characteristics and differences

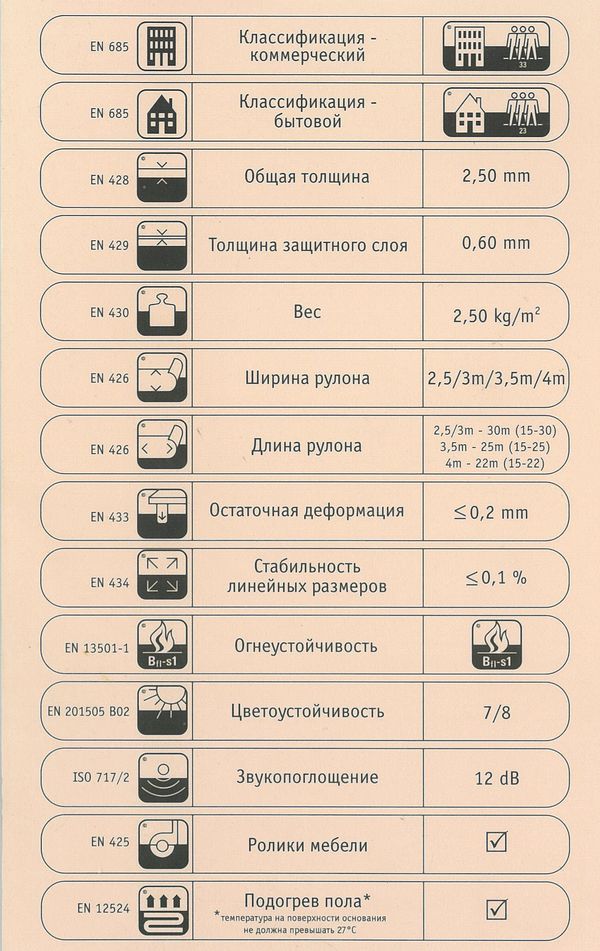

Having ascertained the class of linoleum before the acquisition, we come to the conclusion how much the selected sample is suitable for a particular room. The manufacturer has a pictogram on the packaging as a hint that will help you navigate the purpose of the coating to a person unfamiliar with the numerical designations of the linoleum class.

- 21 class of coverage is designed for rooms with low traffic. A classic example is a bedroom, but if a person lives alone and does not invite guests too often, this is both the entrance hall and the corridor;

- 22 class of material is designed for rooms with medium traffic. A children's room and a living room, if there are not many children and guests - just such rooms;

- 23 class linoleum safely lay in all residential premises, even if their patency is increased. Suitable for the hallway, and for the corridor, and for the kitchen;

- from the 31st class we switch from household to semi-commercial linoleum. This class will adequately prove itself in hotel rooms and low-visited office rooms, but it is often chosen for domestic use;

- Class 32 of linoleum is used in small-format stores, in office premises, in educational institutions (such as a kindergarten or small school). And also popular as home flooring;

- Grade 33 will be justified in an open-space office, school and supermarket;

- 34 class of material is designed for maximum traffic and is able to withstand a large flow of people visiting cinemas, concert venues, government agencies, airports and train stations;

- 41st class - the first of the commercial ones - is laid in production facilities, where employees perform work sitting on the ground. This includes sewing factories and the work of painting artists;

- 42 class of coating will withstand the load from many people, as well as from exposure to reagents, and from small mechanisms and pieces of equipment;

- 43, the wear resistance class of linoleum is the highest, therefore, it is acceptable to use in almost all rooms in factories, warehouses and wholesale bases.

Fire hazard types

Now we will understand what the safety class of linoleum means for its fire-technical characteristics: combustibility, smoke generation, flammability, toxicity and flame propagation speed.

Combustibility is understood as the ability of a material to ignite and maintain fire. This parameter is determined by a number from 1 to 4, linoleum marked with a larger number will be more fire hazardous. Do not stack in places where there is a high probability of the appearance of sources of open fire, sparks, strong heating - in the production workshop in the factory or in the kitchen in the apartment. For such premises, the first or second class of fire hazard of linoleum is suitable.

Smoke generation is an indicator of the optical density of a smoke screen during combustion. Measured on a scale of 1 to 3, with increasing numbers, the density increases.The first type of linoleum for smoke formation is preferable for any room, but with a low flame spread over the surface, linoleum class 2 will also work well. Class 3 is chosen if the first 2 do not fit the budget.

The following types of material according to flammability are distinguished: easily flammable, moderately flammable and hardly flammable. Type names speak for themselves and show whether it is easy to set fire to the sample in question. It is easy to guess that a flame-resistant coating is a priority for any room in the apartment.

Not the last parameter for family health is the toxicity of linoleum combustion products. According to statistics, 75% of victims of fires die from poisoning with toxic substances, so you should play it safe by choosing a floor covering. Marking from T1 (low-risk combustion products) to T4 (extremely dangerous) is affixed after comparing with the standards of GOST 12.1.044-89 SSBT. Data for comparison helps to obtain modern gas detectors, gas analyzers and other laboratory equipment.

According to the speed of flame propagation over the surface, the coating is also divided into 4 categories. But since the room temperature, the presence of wind and the flammability of linoleum will also have an effect, take into account both the marking on the package and these factors.

Also consider with what materials you plan to mount the flooring. Some of them tend to increase the fire hazard of linoleum, or negate the positive properties. A vivid example is fixing non-toxic linoleum with toxic glue.

Choosing the linoleum safety class for fire-fighting specifications for a home purchase, no one expects an EMERCOM officer to come with a check, like to a school or restaurant. But if an emergency happens, the owners will regret that they did not pay attention to safety standards. Take an interest in consultants, check the coincidence of the labeling on the package with the certificate of product quality.

Coating thickness

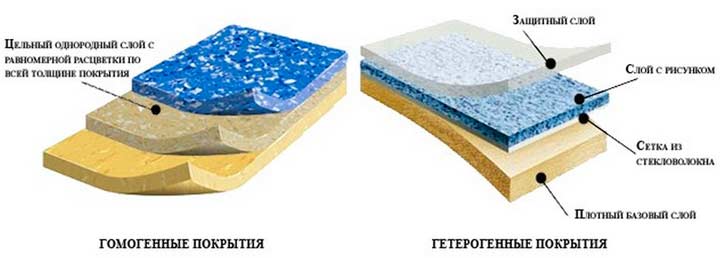

If the natural linoleum on the market of different types and manufacturers is not too different in thickness, then the artificial PVC coating is clearly divided into homogeneous (thin, single-layer) and heterogeneous (thick, multi-layer).

Homogeneous linoleum is homogeneous, indelible, the pattern is applied to the entire depth. It is a recognized leader among flooring for wear resistance. But rarely used in living quarters.

It is softer and more pleasant to walk along the more widespread heterogeneous linoleum; strength is increased by bonding sheets of polyvinyl chloride with fiberglass. Each layer has a separate function, the basic one is necessary for noise and sound insulation, the top protective layer helps to keep linoleum in its original form, a layer with a decor between them.

But builders recommend laying additional substrates of wool, jute, felt, fiberboard or polymers even under multilayer synthetic linoleum. Because the substrate additionally warmly and soundproof the room. Accordingly, the thickness of this additional layer also affects the thickness of the coating. But the determining indicator is the thickness of the linoleum working layer, which will resist loads.

The thickness of the working layer of linoleum of the 2nd class of wear resistance (21, 22, 23) intended for domestic premises is 0.1-0.3 mm. Semi-commercial and commercial, suitable for office - 0.4-0.6 mm. For special linoleum used in industrial premises, the thickness of the working layer is more than 0.6 mm.

Application area

Describing in detail each class of wear resistance of the coating, we gave examples of rooms in which linoleum of one or another class would be appropriate. From these examples, it is clear that linoleum is suitable for almost any room. Be it an apartment, a house, a school, a hospital, a hairdresser.Or even giants like administrative buildings and institutions, shopping centers, factories and factories. Places visited per day by only 2 people or thousands of people.

For a long time, Russians could not imagine decorating without linoleum, because in this price category it is difficult to find a more presentable cover. In addition to useful qualities: durability, reliability, resistance to mechanical damage, linoleum is also characterized by unpretentiousness in installation and maintenance. Every year, the market is filled with new models with additional options: linoleum, which does not stretch, does not tear, is not squeezed by furniture, fire-resistant linoleum. Widespread earlier in kitchens, hallways and corridors, this material supplanted parquet and laminate boards in living rooms as well. nurseries and bedrooms.

What to look for when choosing?

When deciding which class of linoleum is best for home, remember that there is no need to lay linoleum of the same class in all rooms. Choose the linoleum class for each room in the apartment based on the loads that you plan to cover yourself. The manufacturer provides for the load based on averaged values.

Also, do not forget about the appearance and level of comfort of the coating, do not refuse the sample you like, even if the room is not fully compliant with the class. Perhaps the situation will correct the installation of the substrate or special surface treatment.

In addition to pictograms illustrating the wear resistance class of linoleum, there are also pictures on the packaging. Most can be deciphered easily: a picture with a bed indicates the manufacturer's recommendation to lay the cover in the bedroom, with a chair and a table in the office premises, with children's toys in the children's room. If you see a sofa, linoleum is intended for the living room, a faucet with a drop of water - in rooms where the humidity level is elevated, a stove - for dining rooms. A schematic representation of a pipe under the surface in combination with three up arrows indicates the compatibility of the material with heating. The hammer is depicted in order to draw the buyer’s attention to resistance to shock, the sun to color stability, lightning to antistatic properties. The image of the roller wheel of the chair indicates the resistance of linoleum to dents from them, the match - about flammability, the pipe - about sound insulation. These designations will help you choose linoleum suitable for the room.

What does linoleum class mean: Video