Facade plaster Caparol

The name Caparol unites the enterprises of the German concern DAW SE, which produce finishing materials. Including - Kaparol facade plaster. This is a group of polymer and mineral building mixtures that have a number of common functional and decorative properties and are used for exterior decoration of buildings.

The content of the article

Physical properties of Caparol plaster

Due to the chemical composition of Caparol products, decorative plaster has a number of operational qualities.

- The vapor permeability of the coating eliminates the appearance of dampness and the formation of mold.

- Plaster facade Kaparol is steady against atmospheric phenomena, is not afraid of rainfall and temperature drops.

- Fireproof coating.

- The material is environmentally friendly, does not emit toxic fumes.

- Caparol mixes are plastic; plaster is easy to apply to the surface.

Chemical composition

Decorative plaster Caparol is available in two versions: in the form of a dry building mixture and in the consistency of a ready-to-use mortar. They differ in the state of aggregation, origin and composition.

Caparol decorative plaster in the form of a dry mixture is called mineral and has a natural origin. It consists of products based on natural minerals: white cement (made from clay and ground limestone), lime hydrate and organic additives. It is sold in the form of powder in paper packaging and is diluted with water before use.

Caparol polymer (or dispersion) plaster is a ready-to-use mortar. It is sold in hermetically sealed buckets and does not require any other preparation other than tinting, as it is initially white.

Here, polymer resins act as a binder. Depending on the composition, polymer plasters are divided into acrylic (latex), silicone and silicate.

- Acrylic plaster is made on the basis of synthetic resins, from which water is evaporated after application and the binder is polymerized. In the process of polymerization, the molecules form strong bonds between themselves, turning into a monolith.

- The binder in silicone plaster is an aqueous dispersion-based silicone resin.

- The basis of silicate polymer plaster is liquid glass.

When comparing the prices of polymer plasters, we note that the price of plaster on an acrylic binder is lower. This is a common finishing material in the market.

Color spectrum

When choosing both the mineral and polymer versions of the Kaparol mixture, the plaster in the initial state will be white. An exception is the acrylate-based Capatect-Buntstein-Sockelrutz product, filled with crushed stone. A scope - finishing of a socle. This version of the plaster is available in eight colors; the rest of the mixture is tinted to obtain the desired color. The manufacturer offers a palette of pigments presented in a specially developed color map Caparol Color.

Please note: the instruction does not recommend randomly increasing the amount of color pigment during tinting. This affects the physical properties of the coating.

Among the Caparol materials, acrylic-based plasters are resistant to pigments, and mineral mixtures and plasters based on silicone are losing quality due to excess pigment. Therefore, these mixtures are tinted only in pastel colors. To obtain a bright shade that is not in the CaparolColor color map, after the plaster layer has completely dried, the coating is painted with Capatect-SI Fassadenfinish 130 facade paint.

Work on improving the color scheme does not stop. Tinting is carried out on the basis of computer technology Color Express, in the palette of which 5 million shades. At Caparol dealerships, of which there are 500 in Russia, there are color studios equipped with digital equipment to select the exact dosage of pigments.

Texture

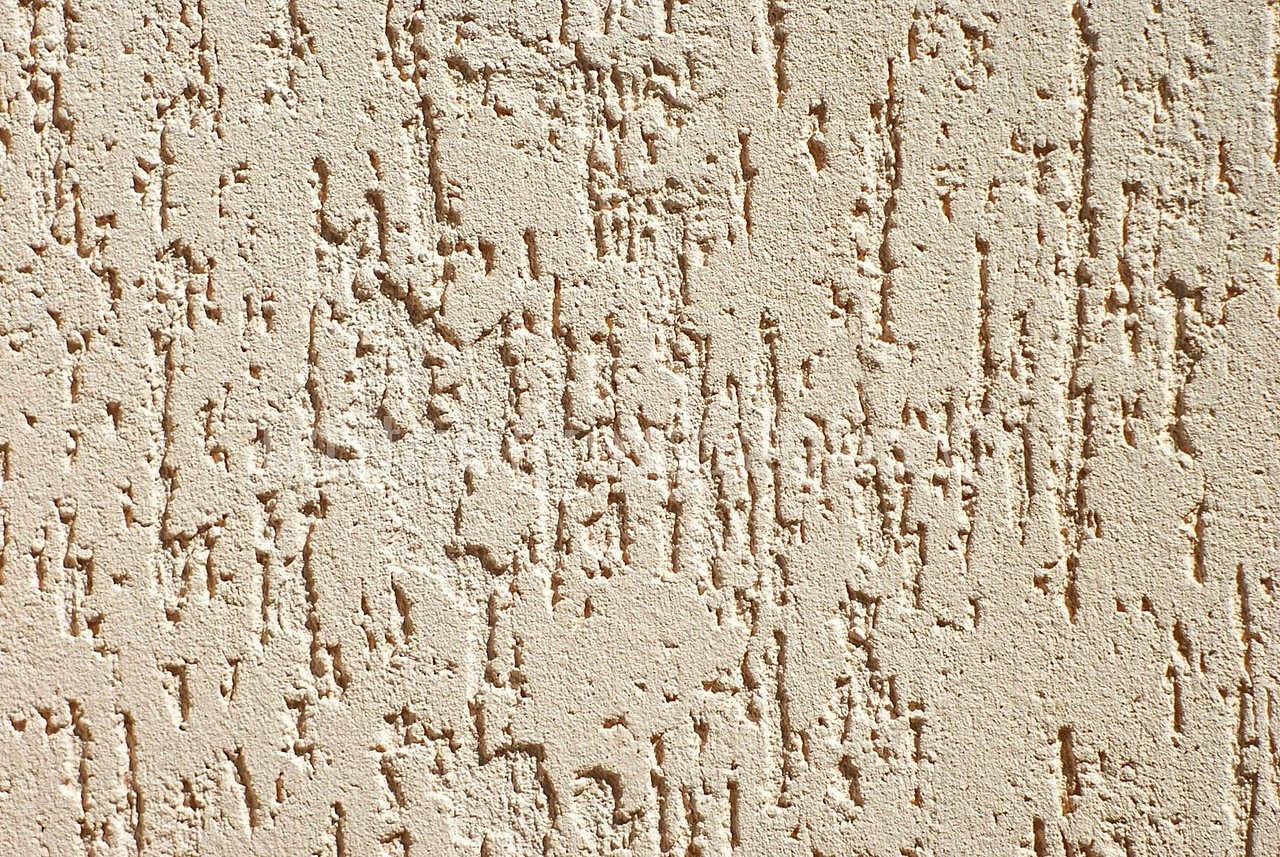

In addition to color, the appearance and structure of the building finished with decorative plaster are affected by the configuration and size of the filler granules. Caparol produces stucco mixtures of three textures: furrowed “bark beetle”, granular “fur coat” and “mosaic” from crumbs of natural stone. Furrowed and grainy are marked with the letter marking: “bark beetle” - R, “fur coat” - K. The numbers next to the letter marking indicate the size of the filler fraction. For example, in the name of the mixture AmphiSilan Fassadenputz R 20, the letter R indicates that it is a plaster with a grooved structure, and the number 20 in the marking indicates that the grain size in the filler is 2 mm.

How to make a bark beetle texture

AmphiSilan Fassadenputz R 20 mixture and fine-dispersed AmphiSilan-Fassadenputz FEIN stucco, both on a silicone binder, form the bark beetle texture from polymeric materials. The furrowed structure is also created by the acrylic mixture Capatect-Fassadenputz R 20 and R 30, reinforced with siloxanes. These are organosilicon polymers in the molecules of which oxygen and silicon atoms alternate.

Mineral plasters with a bark beetle texture - Capatect-Mineralputz R and lightweight Capatect-Mineral-Leichtputz R. The last mixture contains additives that reduce the weight of the mortar.

The direction of movement of the trowel affects the pattern of the surface of the coating: the plaster is applied in circular motions, vertical, horizontal or at an angle.

In the video in this article - a master class on creating the texture "bark beetle.

How to create a texture "coat"?

The “fur coat” structure is obtained using AmphiSilan-Fassadenputz K15, K 20, K30 mixtures on silicone resins and Capatect-Fassadenputz K10, K15, K20 mixtures on an acrylic binder with the addition of siloxanes. Of the mineral compositions, the granular structure of the mixtures Capatect-Mineralputz K and Capatect-Mineral-Leichtputz K.

Lightweight Carparol ThermoSan-Fassadenputze NQG plaster on a hybrid binder based on N.Q.G. technology (nano-quartz lattice), forms both granular and furrowed texture. The composition also includes antifungal, anti-algae and dirt-repellent substances. This thermoplastic material, capable of changing the physical state under the influence of temperature, has influenced the evolution in architectural decoration.

How to plaster a facade with your own hands?

Caparol facade plasters are used for walls of brick, concrete, foam blocks and other building materials. The exception is only plastic and wood: such surfaces cannot be finished with Caparol plasters.

The procedure for plastering the facade:

- Before starting the decoration of the facade, remove dirt from the walls, including oil stains, traces of moss and mold. To do this, use a jet of water under pressure or special cleaning agents.

- Wait for the walls to dry.

- Make sure the surface is firm. In the presence of chips and irregularities, apply a leveling layer of plaster.

- For reliable adhesion of the plaster to the base, the surface is pre-treated with a primer.

- The decorative layer is applied only after the leveling layer has completely dried. This is done by machine or manually using a trowel.

About company

Founded in 1985, Caparol is a family business owned by the fifth generation of chemists. The product line has dozens of materials in which quality and manufacturability are combined with environmental friendliness. To achieve the result, Caparol products require knowledge of the application technology, so the company trains professionals: for this, in 2016, the Caparol Academy was opened in the Moscow region.