How to putty plasterboard ceiling?

Plastering the ceiling from drywall - a stage of construction work, which allows you to prepare the surface for decoration. The quality of its implementation depends on how the finish layer will look, as well as the service life.

Plaster ceiling putty

The content of the article

The choice of putty

Putty is classified by readiness for use:

- Ready composition. Available in sealed buckets. The product does not require preparation, the packaging is opened and the putty is used for its intended purpose. The composition is easy to apply and to apply it, you do not need skills in construction. Therefore, it is recommended to use ready-made putty for non-professionals who carry out DIY repairs. The disadvantage is the high price.

- Dry mix. Available in paper bags. Such a tool needs preparation. The composition is diluted with water in the proportions indicated on the package. To achieve the desired consistency, it is recommended to use a drill with a mixer nozzle. It is difficult to use such putty for people who do not have experience in construction, but it has a more reasonable cost.

The following types of putty are also distinguished:

- Starting mixture. It is applied with a layer of up to 5 mm. The tool is intended for starting treatment of the ceiling. It is applied to the seams, corners and caps of the screws.

- The finish line. Designed to level the surface. It is applied to the ceiling with a layer of 1 mm.

- Universal mixture. It is recommended for use both for the starting layer and for the finishing putty.

Material is classified by composition:

- Gypsum products. The composition does not shrink over time, but it does not provide waterproofing of the surface, since the product is not moisture resistant. Therefore, this putty is not recommended for use in a room with high humidity.

- Cement compounds. The disadvantage is that after the composition dries, defects can form on the surface. Advantages - moisture resistance, which allows the product to be used in rooms with high humidity.

- Polymer putties. Compared with similar products, they have better characteristics, but the price of such a composition is an order of magnitude higher.

Composition Consumption

Before work, the consumption of putty is calculated. This is done so that the funds are enough for the entire surface, from the beginning of the processing of the building base to the finishing application of the layer. When calculating the product, the design feature of the ceiling is taken into account (as in the photo) - the presence of a large number of seams, complex reliefs, corners, etc. The flow rate for such a surface is calculated by the formula:

- 1.1 kg per 1 sq.m. for cement mortar;

- 1 kg per 1 square. m. for gypsum composition;

- 0.5 kg per 1 sq.m. for adhesive based products.

In other cases, the calculation of putty is calculated according to the formula indicated on the package.

What materials and tools are needed?

To putty the ceiling of drywall, you will need tools and materials:

- starting and finishing staff;

- primer;

- containers for diluting the primer and putty (if the mixtures are used not in finished but in dry form);

- set of spatulas;

- drill with mixer nozzle (if dry putty is used);

- grinding grater;

- sickle or paper tape;

- ladder;

- tool for priming the surface (brush, roller or spray);

- molar knife.

Ceiling Putty Algorithm

How to putty the plasterboard ceiling - this question requires detailed coverage.

Surface preparation

Instructions for surface preparation are not difficult. The ceiling is freed from the old coating. Further, the surface is cleaned of dust and dirt. After that, the construction base is leveled. Self-tapping hats should be 1 mm below the surface. If this condition is not met, then it is screwed or twisted to the required level. The surface is also scanned for the presence of an aggressive biological environment. If mold or fungus is found, then the ceiling is treated with special antiseptic agents.

Base coat primer

For priming a drywall ceiling, a deep penetration composition will be required. The product contains film-forming substances, providing better adhesion of the putty to the base. The tool processes a clean ceiling. It is recommended to apply 2 coats of primer. After each treatment, a certain amount of time must pass before the composition dries.

Cooking Tools

If a ready-made composition is used, then it is used immediately after opening the package. Preparation requires only a dry mixture. It is diluted with water in a prepared container. Product to liquid ratios are indicated on the packaging. Next, the composition is whipped with a drill with a mixer nozzle to the desired consistency. The tool should be thick and viscous. Putty is left for a quarter of an hour for infusion, after which it is whipped and used for its intended purpose.

Seam processing

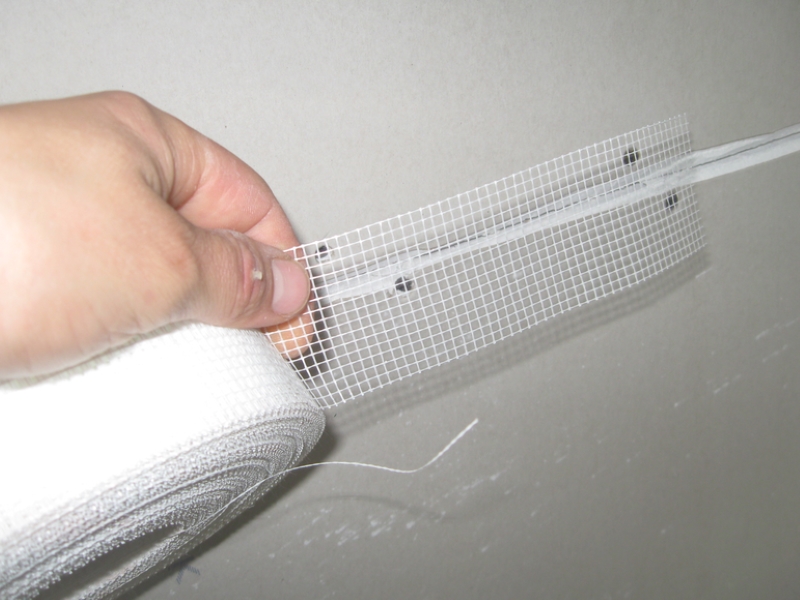

Joining joints is a must-have procedure for plastering the ceiling from drywall. She is using a sickle or paper tape.

Use of a sickle

People who do not have experience in construction, it is recommended to use a self-adhesive sickle, and not simple. Such a tape does not require prior application of the composition to the surface. Self-adhesive sickle sticks to the seam. Then it is processed with putty. Excess funds are removed and the surface is leveled.

Using paper tape

Paper tape is also used to putty seams. It is not as convenient to use it as a self-adhesive sickle, but this material has a more reasonable cost.

Seams are processed putty. After that, work is suspended to dry the composition. Next, paper tapes are glued to the putty using PVA. One more layer of the composition is applied on top.

Putty corners

If the relief of the ceiling is complicated, then you need to putty all the corners of the surface. This is done the same way as in the case of seams, but here it is recommended to use metal corners rather than a sickle. So that they do not extend beyond the surface, the top layer of drywall is removed and primed. Then the corners are fixed, and putty is applied.

Putty self-tapping screws

Hats of self-tapping screws are recommended to be putty with a finishing composition. The tool is applied to small spatulas with two strokes - along and across. The hat cavity is closed with putty.

Putty application

First, the surface is treated with a starting compound. Layer thickness - 5 mm. When the putty is applied to the entire ceiling, you need to wait for the composition to dry. Depending on the type and manufacturer, the drying time is from 6 to 24 hours. After that, the surface is leveled with a grater.

The second layer is applied putty, 1 mm thick. Work also stops until the composition dries.

If we talk about how to putty plasterboard on the ceiling for painting, then the algorithm of work will be the same as for any other finish coating.

Grinding

This is the final stage of plastering the ceiling of plasterboard. Grater processes the entire surface to level it. Work is recommended to be done with glasses and a respirator to protect eyes and mouth from dust.

How to putty the ceiling of drywall is shown in the video in this article.

Knowing how to putty the plasterboard ceiling, you can do the work yourself.