Putty of drywall joints - how to do it

After the drywall is mounted on the walls or ceiling, visible joints remain on the surface of the structure, which does not allow to begin finishing. They, like the places of attachment to the frame, external and internal corners, must be aligned. Anyone can do this - puttying the joints of drywall with your own hands is a simple matter.

The content of the article

What do you need

Tools and materials for this work need a little:

- Putty for drywall joints. You can buy ready-made and just mix until smooth until application. And you can - a dry mixture, but for its preparation you will need a clean container and an electric drill with a mixer nozzle. Instructions for mixing, the ratio of water to powder are on the package, follow it.

- Reinforcing fiberglass mesh in the form of a tape 5-6 cm wide. Sold in rolls or in sections.

Tip. It is important to choose a quality mesh. To do this, it must be actively wrinkled, stretched, folded in half and firmly ironed bend. After all these manipulations, she should return to shape, not burst and not tear around the edges.

- Spatula for applying and smoothing the mortar, as well as angular for processing corner joints.

- Primer deep penetration.

- Sandpaper or sanding grater.

You may also need a screwdriver or a Phillips screwdriver to tighten the protruding screws, a brush and a roller for applying a primer (seeDrywall primer and putty: how to do it right), a vacuum cleaner to clean the surface of dust.

Process steps

To do everything right, follow the rules and recommendations that are given below.

Training

Before you putty the seams on drywall, you need to prepare the surface:

- Screw the protruding screws so that the caps are slightly recessed into the sheets;

- Make chamfers at those joints that are formed not by factory refined edges, but by straight sections. It is more convenient to do this before assembling the sheets, but if such work has not been carried out, then take a paint knife with a sharp blade and cut the edges at an angle of 45 degrees, deviating from the edge about 5 mm;

- Peel the seams of dust and crushed gypsum and prime them. You can start work after the primer has dried.

Putty

Prepare a solution. If it is from a dry mixture, you need to knead it immediately before work and in the amount that you have time to use for the time specified by the manufacturer before setting.

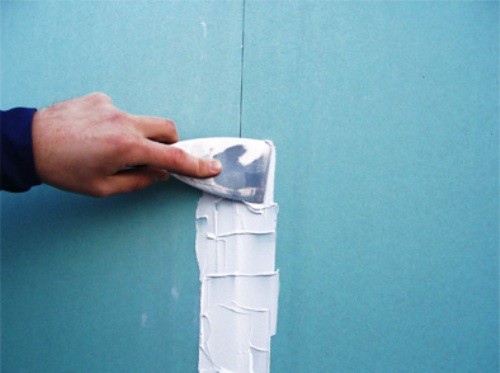

Putty for sealing drywall joints is applied with a spatula across the joints with sufficient force so that it penetrates into the gaps between the sheets. The solution should “bulge” above the surface.

After filling the seam along the entire length, put a reinforcing tape on it, trying to ensure that it lies exactly along the axis of the joint. Then, holding it from above, press the tape with a spatula and guide it vertically downward, pressing the mesh into the solution. It should squeeze through the cells.

Note. When using pieces of tape, they should be stacked with an overlap of 3-4 cm.

After that, change the spatula to a wider one and remove the excess putty with it, aligning the seams along the plane of the surface.

At the joints formed by the cut edges, the tape will protrude above it. To smooth out this thickening, the solution is applied to drywall (seeHow to putty drywall and prevent mistakes) a wide strip, retreating from the seam by 25-30 cm, and stretches flush with the seam.

For reference. Some craftsmen close up such joints without using a sickle. This is possible if the walls will be glued with wallpaper or other materials. It is better not to take risks when painting - the joints may crack, and the paint will not hide this defect.

Now the question may arise: how to putty the seams of drywall in the corners and places where the walls adjoin the ceiling. The internal corners are closed in a similar way, just the reinforcing mesh is bent in the middle.

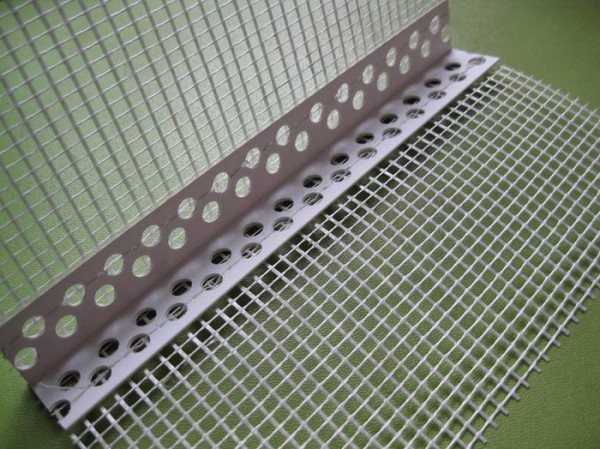

For external corners, it is better to use a special corner, since they are subjected to mechanical influences more often and more intensively than internal ones.

Make sure that all seams and abutments of the planes are smooth, without hollows and bumps. After some time, when the putty for drywall joints begins to dry out, it may slightly settle and “get pulled” into the joints that are not reinforced with a net, forming depressions. Do not immediately coat them, it will be better to level them during a complete putty of the surface.

Grinding

Now you need to wait for the seams to dry completely. The process can be monitored by changing the color of the putty - it gradually brightens from the edges to the center. When the color becomes uniform, you can begin to grind the seams (seeHow to grind walls after putty and how to do it right).

Emery paper is enough for this, but if you want to continue working and putty the entire surface yourself, it is better to purchase a special tool: a grater, on which the abrasive is attached. It can be the same sandpaper or abrasive mesh. Its price is quite acceptable, and it’s much more convenient and faster to work.

All small irregularities, roughnesses and sagging, which may interfere with subsequent alignment, are removed with a sandpaper. At the end of this work, the entire surface is dust-free and completely covered with a primer.

Conclusion

Even the most understandable and well-written text is not able to convey all the nuances of some action. In our case, it is also better to see once how the craftsmen putty the joints than to read a dozen articles about it. Watch the video in this article and try it - you will surely succeed.