Aluminum putty

Aluminum putty - a material that is mainly used in auto repair. The composition is also used in other industries. The main thing is to know the characteristics of the product and the vaccine application.

The content of the article

Material properties

Putty with aluminum dust has the following properties:

- aligns the base;

- hides defects;

- improves the thermal conductivity of the material;

- provides surface waterproofing;

- improves adhesion of the building base to the material;

- facilitates the finish;

- Saves material consumption.

Fields of application

Putty is used in the following areas:

- Car repair. In this area, aluminum putty has become an indispensable material. The composition is used to mask defects - from small scratches to large dents.

- Building. The material is recommended for masking mechanical damage on metal structures. After using the product, the surface is primed and the finish is performed.

- Repair of water transport. Putty is used to repair damage to the body. The tool is easy to apply, so it is recommended to do the repair yourself.

- Fixing polyester laminates. The composition is used to repair the surface of interior items, musical instruments, machine parts, etc., which is made of materials based on polyester resins.

What surfaces is it used for?

The material is recommended for the following types of material:

- steel;

- galvanized building base;

- polyester laminates;

- aluminum;

- lacquered construction base;

- surface coated with an acrylic two-component primer.

Where to get?

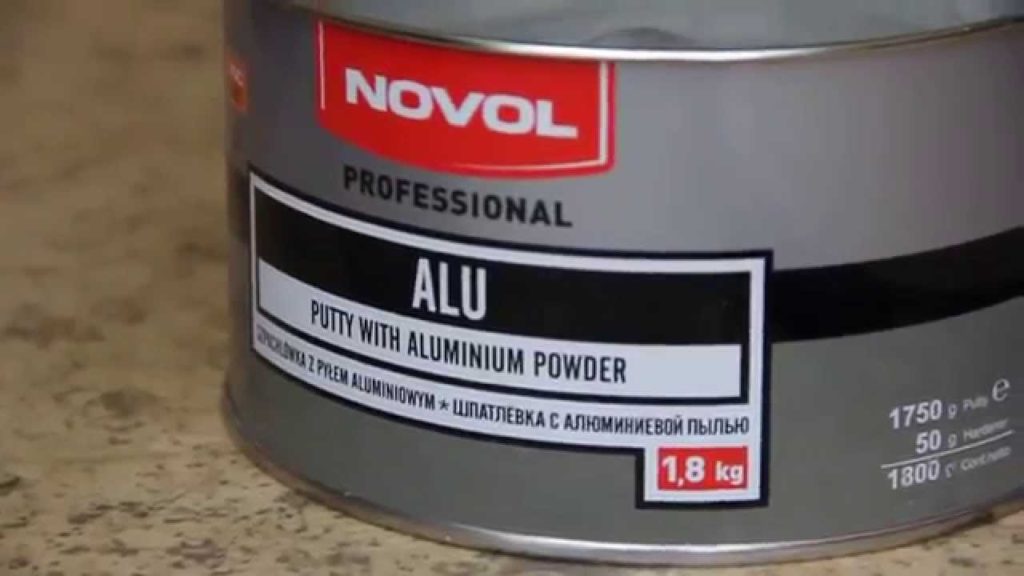

Putties of other types, for example, acrylic, polymer and gypsum, are purchased at retail outlets specializing in the sale of materials for repair and construction. However, a composition with aluminum dust is rare here. Putty is brought under the order. In order not to wait for delivery, the product can be purchased elsewhere. Putty on aluminum is sold at points of sale specializing in auto repair. Price - 500 rubles per 1 kg.

Putty application

When the instructions for using putty with aluminum dust have been studied, even an unprofessional master will cope with the work.

Necessary tools

To apply the composition you will need:

- putty on aluminum;

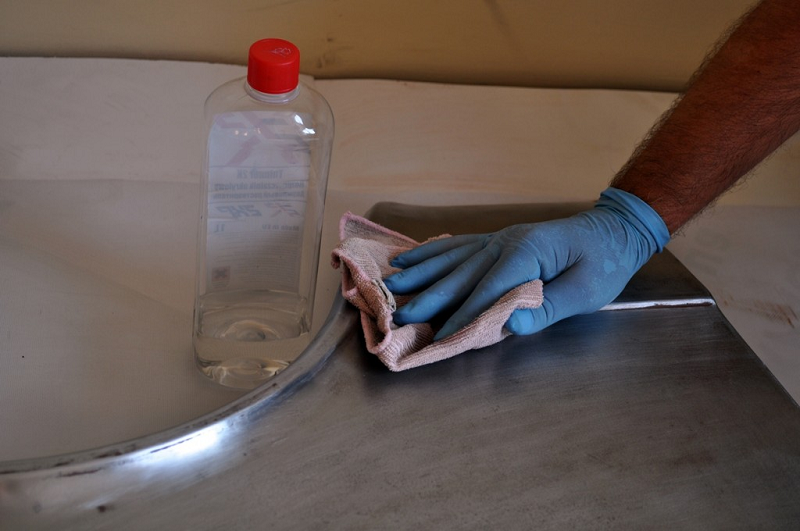

- means for degreasing the building base (it is recommended to use gasoline or kerosene for metal surfaces, and a special tool is chosen for the rest);

- sandpaper for leveling the surface;

- protective equipment (respirator, goggles, gloves)

- set of putty knives.

Surface preparation

The preparation of the building base for the application of putty depends on the surface material:

- Steel and aluminum. Treat the surface with a degreasing agent (as in the photo). below). After that, grind the base with an emery cloth marked P 80, P 100 or P 120. Then remove dust from the surface. Use a construction vacuum cleaner for this. If not, brush the surface with a brush or a broom. The final stage of preparation is repeated degreasing of the surface.

- Polyester base.The preparation of such a surface is similar to the preparation of a surface of steel. Treat the base with a degreasing agent, sand it with sandpaper marked P 100 or P 120 and degrease again.

- Lacquered surface and base coated with acrylic primer. Treat the material with a degreasing agent. Next, clean the surface with sandpaper marked P 220 or P 280. Then degrease the building base again.

Putty application

Putty for aluminum is applied only after the degreasing agent has dried.

Work algorithm:

- Prepare the composition. To make the solution, mix the putty and hardener in a ratio of 100: 3. For a more accurate metering, it is recommended to use a dispenser.

- Measure the temperature. The optimum temperature regime is from +10 to + 200C. If the conditions are not observed, transfer the repair to another time, ventilate the room or install a heater.

- Apply the composition to the surface. To do this, use a rubber spatula. Professional masters allow the formation of sagging, because after the composition hardens, the surface is polished.

- A break in work to putty froze. At a temperature of 200 ° C, the composition freezes in 40 minutes. If you increase to 600 C, the drying time will be reduced to 10 minutes. The temperature is recommended to be raised only if the work needs to be completed quickly.

- When the putty is dry, sand the base. First use coarse sandpaper. After eliminating irregularities, use sandpaper with small particles.

- Coat the surface with a primer. So clean the base from dust that has formed during grinding. In addition, the primer facilitates the finish and extends the operational period of the finish layer.

- Staining. When the primer dries, apply paint to the surface.

The video in this article will demonstrate how to use aluminum putty correctly.

Puttying with aluminum is a simple process, but requires preparation and study. Therefore, before starting work, unprofessional craftsmen should familiarize themselves with the algorithm for filling the surface.