3d wall panels for interior decoration: material features

The term 3d comes from English 3 dimensions, which means 3 dimensions in translation. The idea of using 3d panels to decorate walls inside a house has found its application in modern finishing technologies.

Decorative wall decoration with such panels is becoming increasingly popular.

The content of the article

Technology and materials for the manufacture of 3d panels

At first glance, the technology for manufacturing 3d panels is quite simple.

It consists of three stages:

- At the first stage, the relief of the image is developed, sketches are created and computer models are built.

- At the second stage, design ideas are transferred to the material and processed in accordance with the specified parameters.

- At the third, final stage, the finished panels are finished.

The following materials can be used as finishing materials at the final stage of manufacturing 3d panels:

- paint;

- leather;

- polyvinyl chloride film;

- veneer of valuable species of wood;

3d panels can be made from almost any material from which ordinary panels are formed:

- aluminum;

- polyvinyl chloride (PVC);

- MDF;

- Fiberboard;

- Chipboard;

- natural wood;

- gypsum;

Aluminum

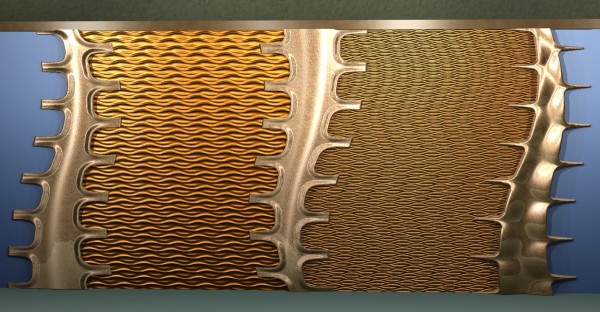

The most widespread are 3d panels made of aluminum.

The pattern is applied to such a panel using perforation and subsequently this pattern is covered with a PVC film.

Such panels have many advantages:

- they have a small weight;

- they are not subject to corrosion;

- fireproof;

- moisture resistant;

- very durable;

- easy to process;

- long term of operation;

Polyvinyl chloride

The second most popular material for the manufacture of 3d panels is polyvinyl chloride (PVC). These panels have the same advantages as aluminum panels, but they have a significantly lower cost.

3d PVC panels produce several types:

- SLR

- smooth;

- textural;

- perforated;

Each type of panel has its own purpose. Perforated panels are great for decorating heating radiators.

Smooth and mirrored panels can be held wall decoration, partitions, doors, etc.

Plastic panels have extremely light weight and high strength. This greatly facilitates installation work.

MDF

One of the expensive materials for the manufacture of 3d panels is MDF. This material is produced by high temperature pressing.

A mold is made for each new series of panels and this affects the cost of the finished product. Thanks to the protective coatings of the 3d panels, their MDFs last quite a long time, but they have a significant drawback - they are afraid of moisture.

The surface relief of the 3d panel from MDF can be made glossy, matte, and even one that glows in the dark, and the choice of colors is generally unlimited. Such panels can decorate any room.

Wall 3d panels are easily mounted. They do not need special care.

They are distinguished by high strength, moisture resistance and sound insulation. Due to their safety and environmental friendliness, MDF panels are perfect for decorating living rooms, including bedrooms and children's rooms.

Fiberboard

Previously, fiberboard was considered not an environmentally friendly material since harmful phenol-formaldehyde resins were used in its production. But nowadays they are increasingly being replaced by lignin.

This natural astringent is released from wood under pressure and at high temperature:

- These panels are made of wood fiber by high temperature pressing.

- They tolerate high humidity pretty well, but are afraid of direct water.

- Such panels do not require special care; sometimes it is enough to wash them with clean water.

To make sure that the panels made of fiberboard are harmless, when buying, ask the seller for a quality certificate.

Chipboard

Another material from which 3d panels are made is chipboard. 3d panels that are assembled from separate chipboard tiles look amazing and unique.

So:

- Using these tiles, you can reproduce a wide variety of compositions. It is impossible to pass indifferently past the wall, which is decorated with such panels.

- Particleboard panels are made by pressing large wood chips at high temperature.

- Covered with a protective film, they can serve for quite some time.

- The disadvantage is that they are afraid of high humidity.

- They can not be used for balconies or bathrooms.

- Particleboard panels do not tolerate sudden changes in temperature, they have less strength than wood, such panels crumble during processing, which is very inconvenient during installation.

Natural wood

One of the most expensive finishing materials interior walls are 3d panels made of wood.

For their manufacture, these tree species are most often used:

- alder;

- oak;

- maple;

- cedar;

Before installation, wooden panels must be coated with wax to prevent moisture from entering the wood:

- Wall panels made of wood give the room a respectable look. These panels do not require special care.

- In order to extend the life of wooden 3d panels, they are periodically rubbed with wax or impregnated with special compounds.

- Wax also prevents cracks on the surface of the panel.

- If you want to install wooden 3d panels in a room where humidity is high, then there must be a ventilation gap between the panels and the wall.

- Wood panels can be used to decorate any room, and everywhere they will be an interior decoration.

- And the main advantage of 3d wood panels is that they are environmentally friendly and have a beneficial effect on human health.

Such panels for many years will retain the aroma and warmth inherent in natural wood.

3d gypsum panels

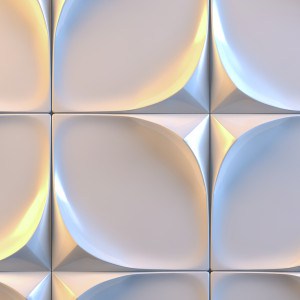

A new direction in the decoration of premises is the use of panels with the effect of 3d from gypsum.

So:

- Due to its amazing aesthetics and variety of drawings, as well as unlimited color gamut, gypsum panels will help to embody any style in the decoration of rooms: retro, classic, exotic.

- Gypsum panels can be mounted on any surface. The only condition is that the surface should be flat.

- These panels are not afraid of moisture, so they can be used in the decoration of any room.

Gypsum 3d panels have several advantages:

- They are easy to mount.

- They create additional sound and heat insulation.

- Gypsum panels have high fire safety.

- After finishing, gypsum panels do not require special care.

So what is a 3d panel

Three-dimensional wall images made of plaster began to decorate the walls before the New Era in Ancient Egypt.

This idea is embodied in modern materials today. Thanks to today's technology, it became possible to create the most complex and unique three-dimensional images.

3d panels are universal and very convenient in interior decoration.

They create an atmosphere of comfort and luxury in any room:

- in apartments;

- in houses;

- in hotels;

- in shops;

- in bars;

- in restaurants;

They are easily mounted on a wooden crate at the same time, there is no need to specially align walls and ceilings. Under the panels you can mount additional thermal insulation, hide electrical wiring, cables, ventilation systems.

Advantages of using 3D panels:

- This is a unique appearance and unique design.

- A wide range of materials, drawings, colors, textures;

- A variety of shapes of products suitable for any interior;

- At any time, you can change the color of the panels, you can even apply the technology of gilding panels.

- Panels with the effect of 3d are made only from environmentally friendly materials.

- Particular attention in the manufacture of panels is given to their fire safety.

- They do not absorb odors.

- They are well protected from mechanical damage.

Summing up all of the above, it is safe to say that wall panels with the 3d effect are becoming increasingly attractive among finishing materials. They are distinguished by their modern appearance and affordable luxury.

You can even trim the volume panel with veneer from such a mysterious material as the root of red mangrove and believe me, this will make an indelible impression.

Finishing 3d panels

The following materials are offered for the finish coating of 3d panels:

- enamel;

- veneer of valuable tree species (beech, ebony, oak, walnut, root of Babona, root of mahogany, Canadian cedar);

- PVC film;

- luminescent coating;

All of these coatings are very strong, durable, have fire-retardant treatment, and environmentally friendly material.Using a PVC film, a natural coating is imitated like wood, leather or enamel.

Enamelled panels can be coated with a luminescent coating. The coating itself is completely safe for human health.

Accumulating light energy for 6–8 hours during the day, the panels begin to glow at night. This charge lasts for 10 hours of continuous glow.

Luminescent coating can be applied both to the entire panel, and to its individual parts.